Automated Multi-Purpose Tester UTP 9085

- Home

- Test and Automation Systems

- Automated Multi-Purpose Tester UTP 9085

AUTOMOTIVE, SMART HOME, TELECOMMUNICATION

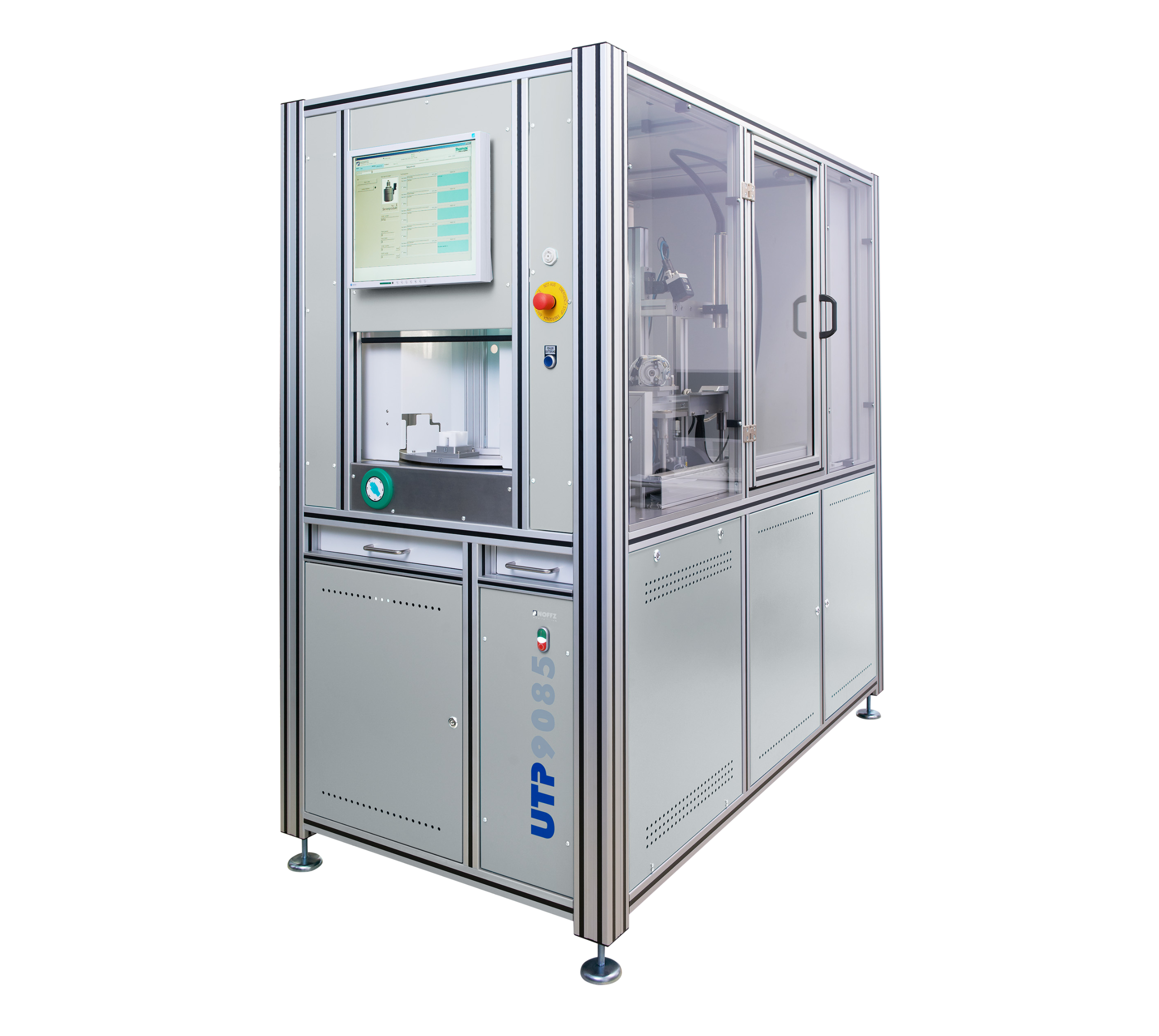

Automated Multi-Purpose Tester UTP 9085

The UTP 9085 is a fully automated, multi-stage test system within the NOFFZ Universal Tester Platform (UTP).

Designed for high-volume production environments, it combines automated DUT handling, multi-station workflows, and modular test instrumentation in one compact platform. The system enables rapid cycle times, reliable end-of-line processes, and seamless integration of inspection, labeling, and functional testing – all within a highly flexible and scalable architecture.

THIS IS WHAT DISTINGUISHES OUR PRODUCT

Features and Specifications

- Automated rotary/indexing table: Moves DUTs through multiple test and inspection stations in a continuous, fully automated sequence.

- Multi-DUT capability: Supports dual-DUT or multi-nest setups for increased throughput and parallel processing.

- Integrated process automation: Optional modules such as optical pin/connector inspection, label printing and application, and automated sorting can be included.

- Modular UTP instrumentation: Supports a wide range of signal types, measurement needs, communication interfaces, and power requirements.

- Customizable DUT adapters: Exchangeable fixture concepts allow fast changeover between product variants and future product generations.

- UTP software suite: Provides test sequencing, variant management, data logging, traceability, MES/IT connectivity, and full automation control.

- Compact, space-efficient design: Combines multiple test steps into a single integrated station, reducing system footprint.

Advantages

- High throughput through continuous, automated multi-stage processing

- Reduced manual labor with automated handling, labeling, and inspection

- Consistent and repeatable quality via controlled, automated test flows

- Fast variant changes supported by modular adapters and software-based configuration

- Lower total cost of ownership by integrating multiple production steps in one system

- Scalable and future-proof to support new test requirements or expanded product families

Typical Applications / Different Variants

Typical Applications

- End-of-line testing for electronic control units

- Inspection and functional validation of mechanical-electrical assemblies

- High-volume production lines requiring automated labeling and sorting

- Multi-step verification processes such as assembly check + functional test

- Products requiring connector inspection to prevent contact failures

Possible System Variants

- Dual-DUT or multi-nest configurations for higher throughput

- Extended instrumentation versions for complex electrical or communication interfaces

- Enhanced automation variants including robotic handling or custom inspection systems

- Compact or extended table sizes based on cycle time and station requirements

- Specialized adapters for unique product geometries or test constraints

MODULAR EXPANDABLE

Various versions of the UTP 9085 test series

Variants of the UTP 9085 include various configurations such as the NAD module and the 5080 adapter for semiconductor testing. In combination with a robot, this creates a complete UTP 9085 test cell.

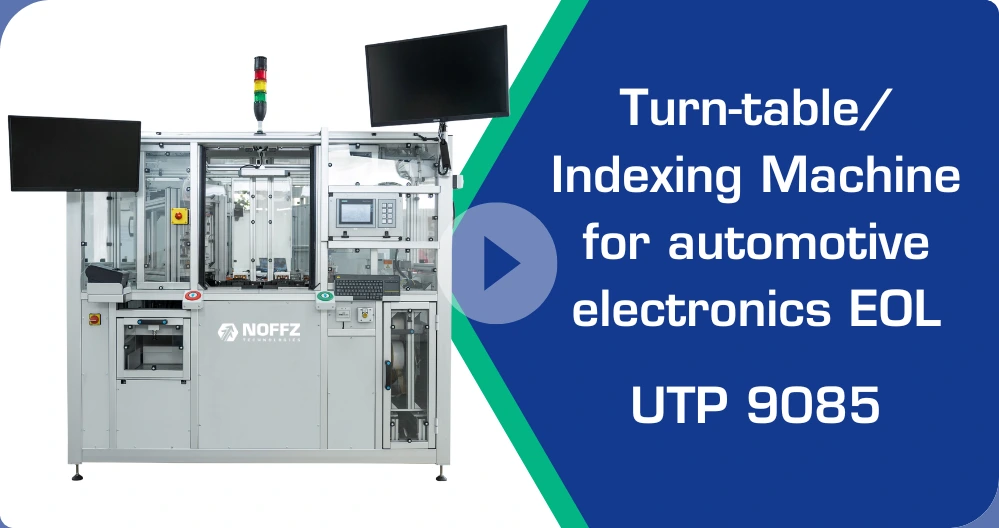

UTP 9085

End-of-Line Tester

Turn-table/Indexing Machine for automotive electronics EOL testing

UTP 9085

End-of-Line Tester

Rotary Transfer Machine for Testing Locking Magnets

UTP 9085

High-End Amplifier Tester

Robotic coating test station

UTP 9085

End-of-Line Tester

Tester for automotive components with vision, button press, and communication testing.

UTP 9085

End-of-Line Tester

Fully automated rotary test system for high-volume, multi-process validation with maximum flexibility.

UTP 9085

End-of-Line Tester

High-performance LTE NAD test system for flashing, calibration, verification, and packaging in one solution.

IN ACTION

NOFFZ UTP 9085

Rotary table/indexing machine for EOL tests in automotive electronics

Introducing our latest automation solution: the UTP 9085 rotary and indexing machine. This state-of-the-art technology offers a comprehensive range of functions: rotary table and robot integration, multi-stage end-of-line inspection with double unit under test (DUT), optical pin inspection, label printing and application.

Automated systems for high-performance testing

Discover how modular automation components and robot-assisted integration boost throughput, precision, and reliability across a wide range of test applications. To learn more, click the button below.

DO YOU HAVE ANY QUESTIONS?

Speak with our experts directly!

Let us know the details of your project. We’re curious about your ideas, products, and requirements and would be glad to advise you specifically about your requests.

Together we’ll make your project a success!

Let’s set up a meeting.