The automotive industry in transition

Test and inspection systems for electromobility

The demand for test systems for e-mobility is increasing

Our mobility is undergoing a radical change – electric motors are increasingly replacing the use of combustion engines.

A logical decision for our future: We all know that fossil fuels are not infinitely available, which makes renewable energies necessary; we also know that electric mobility is significantly more environmentally friendly, quieter and, in the future, also cheaper.

For the e-mobility sector, NOFFZ Technologies develops customer-specific test system solutions for validation as well as functional and end-of-line testing.

Our systems are scalable in all test areas. Starting with single tests of control modules up to complete solutions of test tracks.

We offer a comprehensive portfolio with many variable concepts based on test requirements.

Inverters

Test systems for DC/AC inverters

The heart of an electric vehicle is its powertrain. This includes the battery, electric motor, and inverter or converter components. Inverters convert the battery’s direct current into usable alternating current for the electric motor.

NOFFZ Technologies offers complex test solutions for your inverters – for validation in endurance or functional tests and for production in the end-of-line area.

Validation Tester UTP 9065 Run-in/Screening Test System

Our UTP 9065 Run-in/Screening test solution was developed for modern e-mobility powertrain components, control components, and battery packs. It is specifically designed as a validation test environment where multiple devices are tested in parallel over long periods of time under different environmental factors. However, it is also perfectly suited for development or production scenarios.

The run-in/screening test system can perform parallel tests in different temperature ranges between –40 °C and +85 °C (–40 °F to +185 °F). In addition to the connection to a customer database and the iTAC system, the variant management tool makes individual contacting and measurement of the DUTs possible and allows for storage of module-specific temperature curves.

Measurement technology

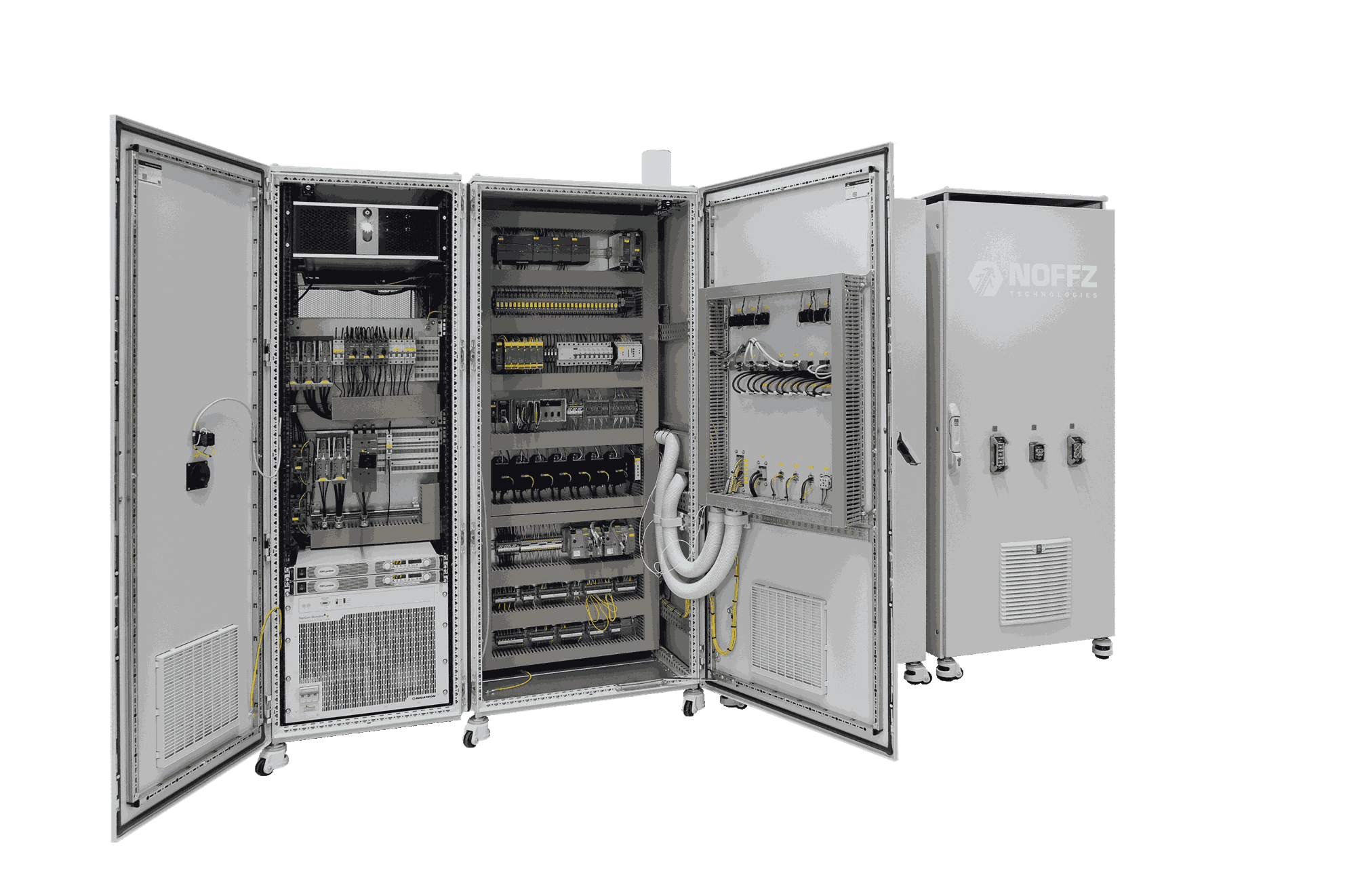

UTP 7042 end-of-line tester for powertrain components

The UTP 7042 series is a test platform for the EOL and the FKT area. It can be used to carry out a wide variety of performance, functional and communication tests.

The basic UTP 7042 system can be equipped with variable measurement devices and power supplies. It can be used as a complete, scalable, and modular test system. The UTP 7042 is the perfect system solution to handle control, measurement, and supply of the DUT in case of a corresponding DUT handling cell, no matter if automated or manual setup is intended.

Components

- 19” Rack

- Rack Accessories

- Touch Display

- IPC

- Emergency Power Off

- Power Distribution Unit

- kW Power Supply

- Power Load Matrix

- PXI Instruments

Battery

Test systems for battery modules

with battery management system

The battery is the storage medium of the electric vehicle. It provides the necessary energy for all components involved in mobility. High-voltage batteries with output voltages between 400 V DC and 800 V DC are used. A battery consists of numerous cells connected in parallel and series, which jointly form a so-called stack. This unit is controlled and monitored by a battery management system (BMS). The task of the BMS is to provide the necessary cell balancing, prevent short circuits, and protect against overheating.

In order to reliably test battery systems, NOFFZ Technologies offers an innovative test concept that simulates charge cycles and load cycles.

We use the DC supply to charge the battery and the electronic DC load to simulate the output loads (e.g. inverter/converter). The battery and the upstream battery management system are connected via a CAN interface, which is used to communicate and control the battery. The battery is also tested: Current data such as charge status, input and output current, voltage of individual cells, and the temperature of the batteries can also be read and logged from the BMS.

Validation Tester UTP 9065 Run-in/Screening Test System

Our UTP 9065 Run-in/Screening test solution was developed for modern e-mobility powertrain components, control components, and battery packs. It is specifically designed as a validation test environment where multiple devices are tested in parallel over long periods of time under different environmental factors. However, it is also perfectly suited for development or production scenarios.

The test system can perform parallel tests in different temperature ranges between –40 °C and +85 °C (–40 °F to +185 °F). In addition to the connection to a customer database and the iTAC system, the variant management tool makes individual contacting and measurement of the DUTs possible and allows for storage of module-specific temperature curves.

Measurement technology

FKT Run-In Tester UTP 9080

for battery packs with battery management system

We develop versatile and extensive software applications, where your respective test product is always the focus of our programming approach. Our experts primarily use the following software environments:

NI LabVIEW, NI TestStand incl. Semiconductor Test Module, Python, C++, C# and .NET.

Of course, your product variants are covered by a professional variant management system. The test results are summarized in reports and integrated into your database, if required.

Our applications are modular and therefore scalable at any time. This means that you are ready for future requirements right from the start. Depending on your internal capacities, we support you on a project basis or long-term. We will also gladly assist you directly on site.

Advantages

- Number of test cells is expandable

- Inline or offline variants available

- Full automation possible

Charging systems

Test solutions for EVSE charging systems and wallboxes

Refueling with fossil fuel has been replaced with supply of electricity through charging systems.

In this process, electric vehicles can be charged with electrical energy via different charging devices, which is then temporarily stored in the batteries and passed on to the engine.

EVSE (Electric Vehicle Supply Equipment) rapid charging systems convert AC voltage from the grid directly into DC current for the battery. EV wall charging stations, known as wallboxes, on the other hand, do not convert the AC voltage from the domestic junction directly into usable DC voltage. An on-board charger (OBC) is used for this intermediate step. It is installed in the vehicle and handles authentication of the electric vehicle at the charging station.

NOFFZ Switch and Load Boxes

NOFFZ Technologies offers a solution for secure testing of EVSE charging systems and EV wall charging stations (wallboxes) for any test environment.

The focus of our test solution is the communication between EV wall charging station or EVSE charging system. The electric vehicle is connected to the charging station via a charging cable in which a control box, the ICCB (In-Cable Control Box), is integrated:

Using our NOFFZ switch and load boxes, various changing faults and situations can then be simulated to test the behavior of the landing terminal and the vehicle in response to this situation. In parallel, all electrical variables required and relevant for the customer are measured and logged. In addition, the software of the test system takes over the control of power sources and sinks.

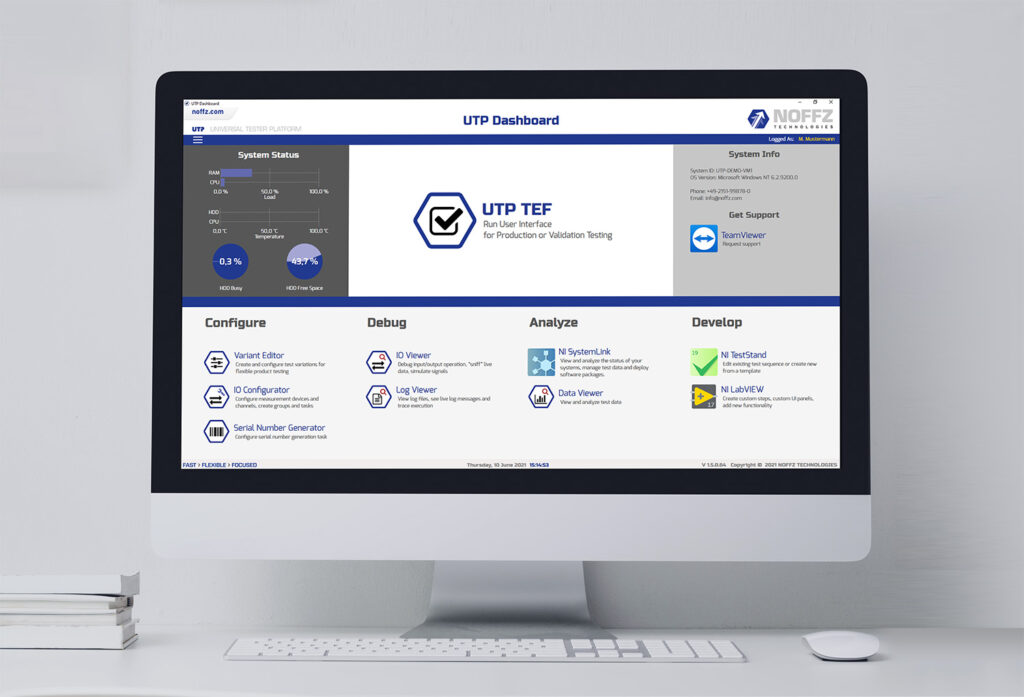

Software

Software UTP Suite

Our universal test software UTP Suite is the core element of our test systems. It is successfully used from product validation to production testing.

The software is based on established test environments such as NI TestStand, NI LabVIEW and .NET.

The UTP Suite makes extensive tester configurations and higher-level tester administration possible. Thanks to a simple modular system, it can be individually tailored to the respective requirement and the test object.

It covers comprehensive tasks such as product variant management, product traceability, data reporting and analysis, abstraction of hardware and measurements, as well as software distribution.

Our mobility is changing

The drive technology of the future is here: fuel cells

NOFFZ Technologies, in partnership with Albert & Hummel GmbH, offers advanced automation and testing solutions for the efficient mass production of fuel cell systems. Their systems support the entire production cycle, from development to serial production, ensuring high quality and reliability. These solutions are flexible, scalable, and Industry 4.0 compliant, designed to enhance production capacity while reducing costs. Noffz’s systems integrate various complex manufacturing steps, crucial for the future of clean energy mobility.

For more details, please visit Fuel cell technology page.

DO YOU HAVE ANY QUESTIONS?

Speak with our experts directly!

Let us know the details of your project. We’re curious about your ideas, products, and requirements and would be glad to advise you specifically about your requests.

Together we’ll make your project a success!

Let’s set up a meeting.