FLT 150A

Fast Transient DC Load

E-load platform for next-gen pmic validation

For development, prototyping, and especially post‑silicon validation of modern power‑management ICs, highly dynamic and precisely controlled load instruments are essential. The FTL 150A delivers deterministic load transients with high slew rate, enabling detailed characterization of PMIC responses under realistic conditions.

If your validation process requires fast, repeatable current transitions, precise trigger signals, and perfectly time‑aligned measurements, the FLT 150A is the ideal solution for your workflow.

Precise, Time‑critical Load Emulation – Efficient & Reliable

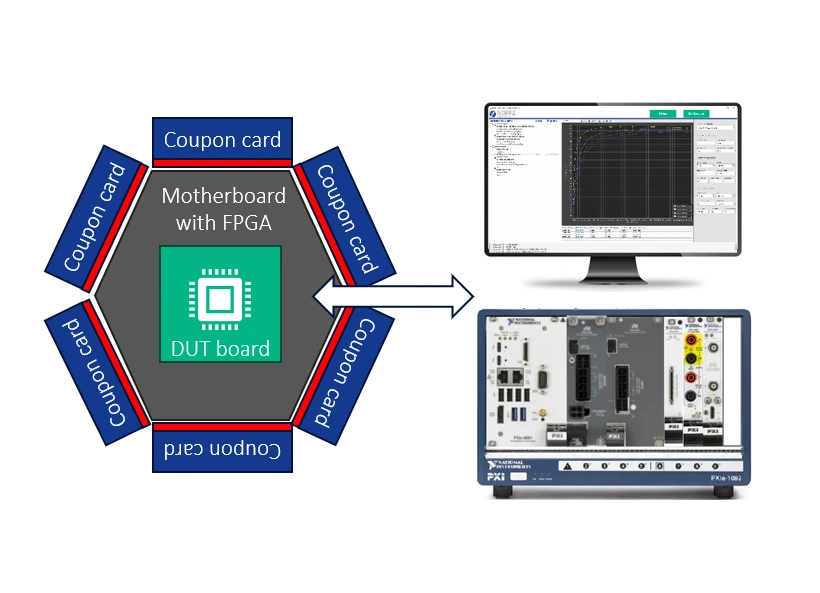

Designed specifically for high‑speed load‑step testing, the FLT 150A achieves slew rates up to 150 A/µs with 200‑ns pulse timing resolution. Its FPGA‑based architecture guarantees nanosecond‑level timing determinism, enabling perfect correlation between load events and voltage responses.

The platform integrates seamlessly into modern measurement environments – fully automated, scriptable, and ready for advanced validation tasks requiring precision and repeatability.

THIS IS WHAT DISTINGUISHES OUR PRODUCT

Features and Specifications

- High‑bandwidth current control: Real‑world transient emulation up to 150 A/µs with 200‑ns timing resolution.

- Accurate, time‑aligned measurements: 20‑MHz Rogowski coil, precision Hall sensor, 50 MS/s voltage and current acquisition

- Flexible synchronization & triggering: Import/export digital triggers to align external measurement equipment

- Modular power architecture: Up to 6 scalable power coupon cards for current expansion

- Robust high‑power design: Built‑in protections, controlled thermal behavior, planar magnetics

- Low‑inductance DUT connection: Utilizes a high‑density Samtec SOLC connector for fast transient operation

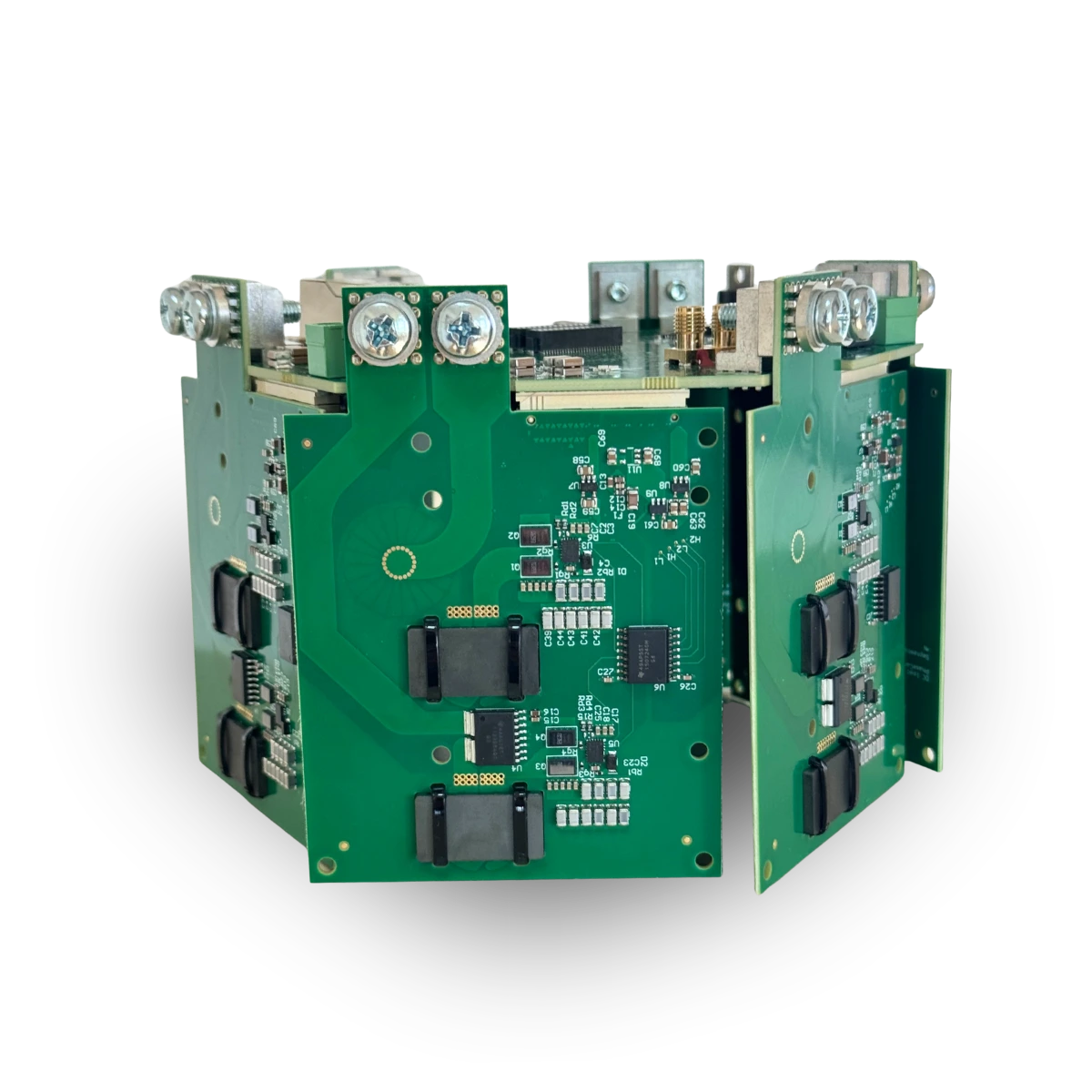

Picture of the FLT 150A

Advantages

- Ultra‑fast load transients up to 150 A/µs for realistic PMIC stress tests

- High‑accuracy measurements via 20‑MHz Rogowski coil & 50 MS/s acquisition

- Nanosecond‑level determinism with FPGA‑based control

- Flexible synchronization through trigger in/out

- Smooth integration using LabVIEW, Python & NI plug‑ins

- Modular, scalable design using power coupon cards

- Robust high‑power platform with built‑in protection & thermal stability

Software & Automation

The FLT 150A is built for automated workflows.

All functions are accessible via modern software APIs or an intuitive interface.

Industrial grade

- LabVIEW and Python APIs for automation and system integration

- NI InstrumentStudio Measurement Plug‑In for ready‑to‑use transient load tests

- Programmable transient waveform control for realistic load profiles

- Synchronized control & acquisition for perfectly time‑aligned analysis

Technical Data

Performance

Measurements

System Architecture

- Continuous current: 150–200 A

- Voltage range: 0.3–12 V

- Continuous power: <500 W

- Max. Max. slew rate: 150 A/µs

- Minimum pulse on‑time: 400 ns

- Pulse duration resolution: 200 ns

- Voltage: 50 MS/s, 8‑bit adjustable range

- Current: Hall (1 MHz) + Rogowski (20 MHz), 50 MS/s, 13‑bit recording

- Protection: Over‑current protection

- Synchronization: Digital trigger import/export

- Motherboard: 150 × 150 × 25 mm

- Coupon cards: 70–75 × 10 × 40 mm

- Complete system: 250 × 250 × 100 mm

- Communication: Ethernet

- Integration: Works directly with NI PXI for DUT power, interfaces, synchronization, and monitoring I/Os

Connections & System Integration

The FLT 150A provides versatile connectivity for lab, validation, and production settings:

- Samtec SOLC high‑density DUT connector

- Digital trigger in/out

- Ethernet communication

- Expandable current stages via modular coupon cards

Optional Accessories

- Rackmount kit for integrating the system into 19″ racks (aligned with other NOFFZ product options)

- Expansion cards for higher current capacity

- NI PXI add‑on modules for additional monitoring & control

Downloads

Our brochures for download

DO YOU HAVE ANY QUESTIONS?

Speak with our experts directly!

Let us know the details of your project. We’re curious about your ideas, products, and requirements and would be glad to advise you specifically about your requests.

Together we’ll make your project a success!

Let’s set up a meeting.

Ales Zitek

Sales Manager Eastern Europe NOFFZ Technologies Hungary Kft.

Automotive devices must be reliable.

Combine all products and

measuring instruments in just one rack for validation.

Test devices with high channel counts in parallel.

Modify satellite trajectories. Simulate environments.

Generate a variety of realistic multiband GNSS signals. Define your parameters individually and test them with high precision. Directly in the lab and in real time.

Efficiently test wireless communication devices with a system designed for high-volume parallel testing. It integrates multiple wireless standards into one platform, allowing you to use up to 64 ports simultaneously.

Larger displays and increasing connectivity.

Improved technologies are setting a rapid pace.

These innovations require intelligent test systems.

We create your individual solution with high precision.