Multi-DUT Run-In / Screening Tester UTP 9065

- Home

- Test and Automation Systems

- Multi-DUT Run-In / Screening Tester UTP 9065

AUTOMOTIVE, SMART HOME, TELECOMMUNICATION

Multi-DUT Run-In / Screening Tester UTP 9065

The UTP 9065 is a scalable, high-parallel test system within the NOFFZ Universal Tester Platform (UTP). It is optimized for long-duration functional testing, environmental screening, and run-in processes across a wide range of electronic assemblies.

With its highly modular design, UTP 9065 enables the efficient validation of multiple DUTs under identical and repeatable test conditions.

THIS IS WHAT DISTINGUISHES OUR PRODUCT

Features and Specifications

- High parallelization: Supports simultaneous testing of multiple DUTs in one system, enabling significantly higher throughput for run-in, screening, and aging processes.

- Environmental & long-duration testing: Designed for operation within environmental chambers, covering extended temperature ranges (e.g., –40 °C to +85 °C). Suitable for thermal cycling, stress tests, and endurance conditions.

- Flexible DUT & variant handling: Modular fixture concepts and adaptable interfaces allow quick reconfiguration for different product variants, ensuring future-compatibility.

- Automated test execution & data traceability: The UTP software suite ensures fully automated test sequencing, comprehensive logging, and connectivity to customer databases or production-IT systems for complete documentation.

- Scalable hardware platform: The system follows the UTP architecture with modular instrumentation, flexible I/O expansion, and configurable signal routing tailored to your specific DUT.

Advantages

- Modular test architecture for flexible signal types, measurement ranges, and interface technologies

- Customizable adapters designed for specific DUTs and optimized contact reliability

- High-performance real-time execution for synchronous, parallel measurement tasks

- Centralized UTP software suite providing test control, variant management, data acquisition, and system integration

- Cross-industry adaptability for automotive, e-mobility, industrial electronics, consumer electronics, and more

- Significantly increased throughput through true multi-DUT parallel testing

- Reduced cost per DUT thanks to shared instrumentation and automated processes

- Broad range of test coverage combining functional, environmental, and long-duration testing in one platform

- Future-ready design that adapts to new product generations and interfaces

- Enhanced quality assurance through detailed logging, traceability, and reproducible test conditions

Typical Applications / Different Variants

Typical Applications

The UTP 9065 is an established solution for high-volume run-in and screening scenarios, such as:

- Functional long-duration tests of electronic modules

- Thermal stress and endurance testing under extreme temperature conditions

- Screening of safety-relevant or communication-relevant modules

- Multi-DUT validation during development or pre-production phases

- High-throughput testing of control units, power electronics, or sensor-based assemblies

MODULAR EXPANDABLE

Various versions of the UTP 9065 test series

UTP 9065

Product Validation

Validation of infotainment test systems for a German Tier 1 supplier.

UTP 9065

Dual-drawer system with 28 modular slots, flexible interfaces, RF testing, and PXI-based automation for high-performance validation.

UTP 9065

Product Validation

Monitoring tester for 5G modules.

UTP 9065

Product Validation

Validate up to 8 DUTs in parallel with real-life reliability testing, fully synchronized with environmental stress systems

configuration

Sample configuration

Feature

Multi-DUT Capacity

Environmental Capability

Instrumentation

Software Framework

Typical Test Types

Scalability

Description

Usable inside temperature chambers for thermal screening from approx. –40 °C to +85 °C

IN ACTION

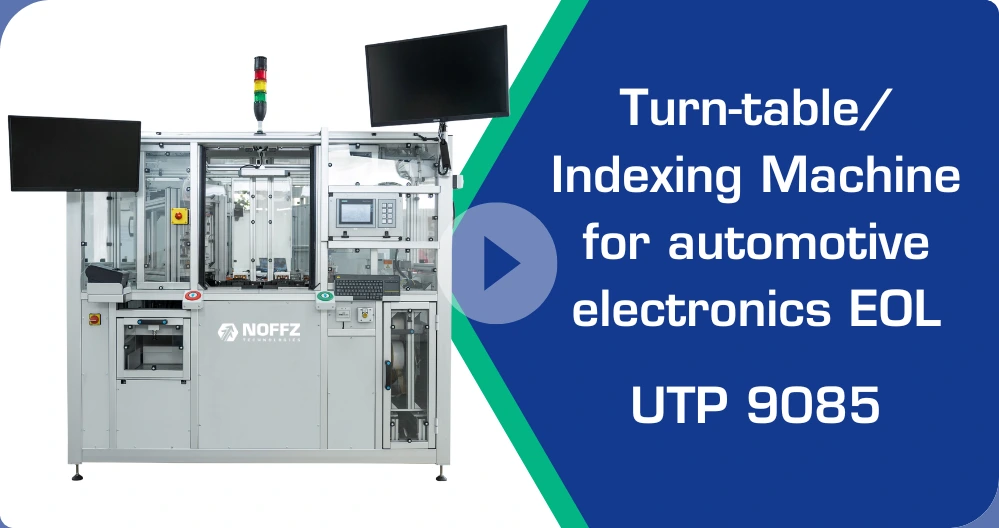

NOFFZ UTP 9085

Rotary table/indexing machine for EOL tests in automotive electronics

Introducing our latest automation solution: the UTP 9085 rotary and indexing machine. This state-of-the-art technology offers a comprehensive range of functions: rotary table and robot integration, multi-stage end-of-line inspection with double unit under test (DUT), optical pin inspection, label printing and application.

Automated systems for high-performance testing

Discover how modular automation components and robot-assisted integration boost throughput, precision, and reliability across a wide range of test applications. To learn more, click the button below.

DO YOU HAVE ANY QUESTIONS?

Speak with our experts directly!

Let us know the details of your project. We’re curious about your ideas, products, and requirements and would be glad to advise you specifically about your requests.

Together we’ll make your project a success!

Let’s set up a meeting.