RF Tests

APPLICATION

RF Testing in a Connected World

Living in a Connected World

What is RF testing?

RF testing plays a vital role in verifying the performance and reliability of wireless systems and electronic devices. It helps identify and address issues such as signal interference and system inefficiencies, ensuring devices meet regulatory standards and function effectively in practical applications. By conducting RF tests, manufacturers can reduce the risk of failures, improve device quality, and ensure smooth operation. This process is essential for certifying and maintaining technologies that depend on radio frequencies, from everyday electronics to advanced industrial tools, giving companies an advantage in a highly connected market.

Challenges and solutions

Importance of RF Testing

The importance of RF technologies cannot be overstated. It is the invisible force keeping our devices communicating harmoniously, making the promises of a connected lifestyle a reality. Yet, the complexity of RF testing poses a formidable challenge: instrumentation is expensive, and know-how is scarce. DUTs (Device Under Test) apply a wide range of functionality from the low-channel count, simple devices (smart meters, industrial IoT modems, wearables) to highly integrated products with a dozen or so RF ports (TCUs – telematics control units, smart gateways, smartphones). Each of these devices needs scalable, focused RF test solutions. In an era of rapid development and short time to market, engineers began questioning traditional testing methods.

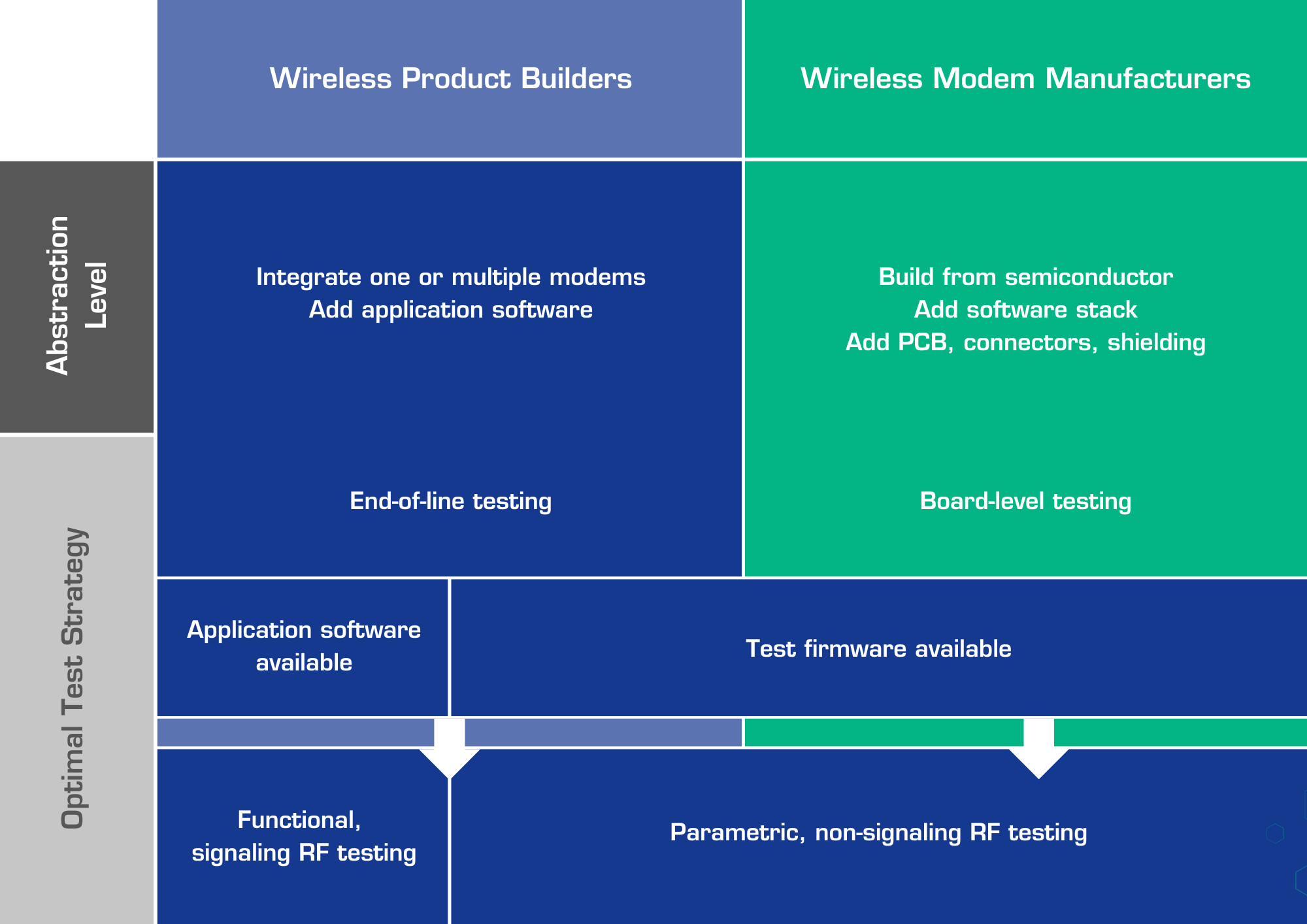

What is the difference between functional test and parametric test?

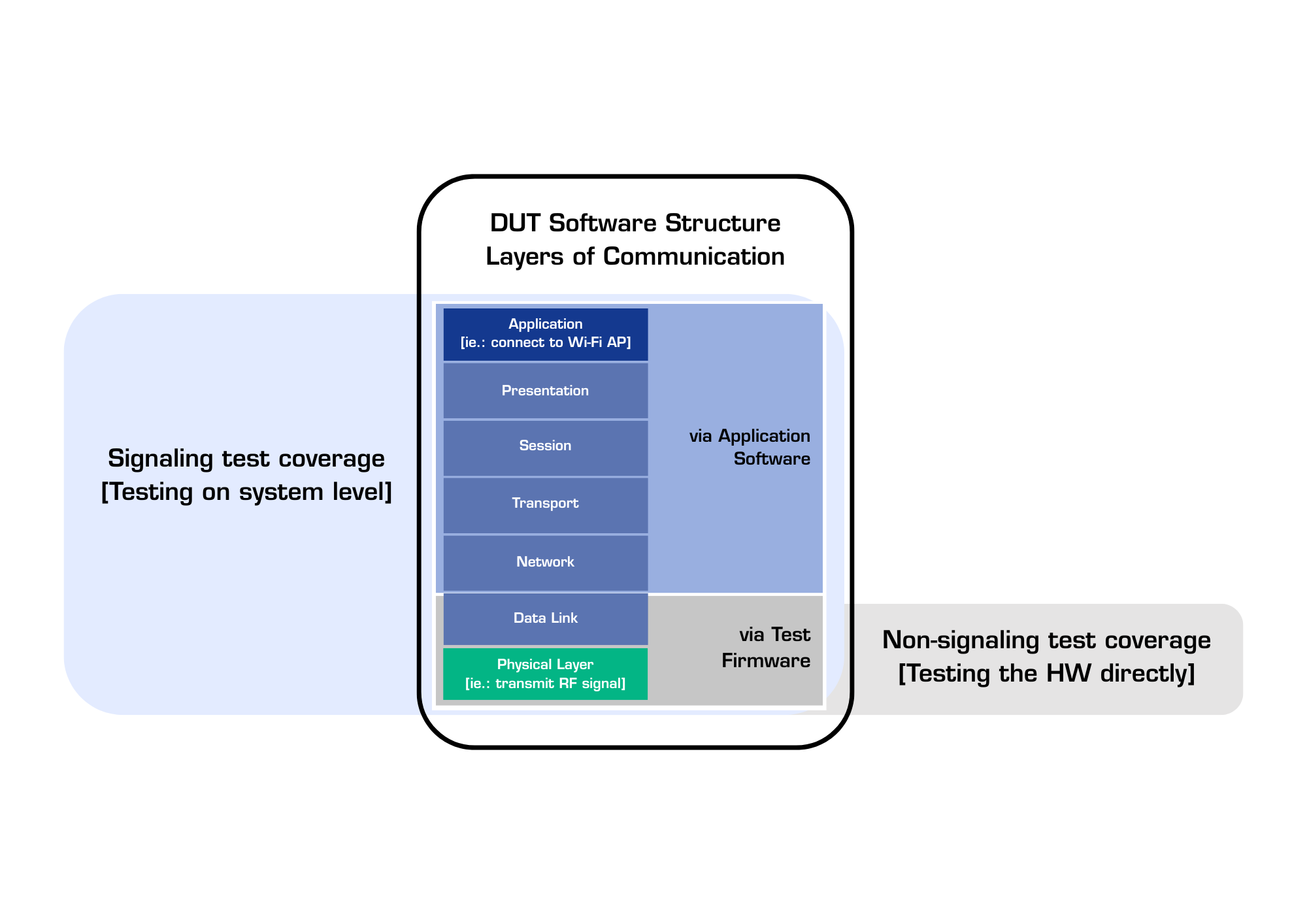

RF parametric testing is a repeatable, fast technique to evaluate the physical layer qualities of a wireless modem, often executed in the form of non-signaling testing, while functional testing approaches quality analysis from the application layer, also referred as signaling test, offering lower costs, but longer test times.

RF parametric testing has always been the go-to option in manufacturing. Non-signaling testing is equivalent to high-speed and thorough quality assurance. Tackling high channel counts (MU-MIMO), efficient instrument sharing, keeping up with the new release of wireless standards (5G NTN, Wi-Fi 8), covering wide frequency ranges and co-existence of utterly different radio types (BLE and UWB) makes it challenging to select the right instrumentation. In this cloud of requirements, open and modular platforms lead the way towards clarity.

As non-signaling testing is the best option in many cases, it is simply not affordable to apply this technique at each abstraction level. Product builders – who purchase one or more wireless modems and integrate them into a complex, high-level device – focus on system-level verification rather than the low-level quality of all components.

Wireless device test strategies

Signaling vs Non-signaling Test Coverage

Overview NOFFZ products

NOFFZ products

IN ACTION

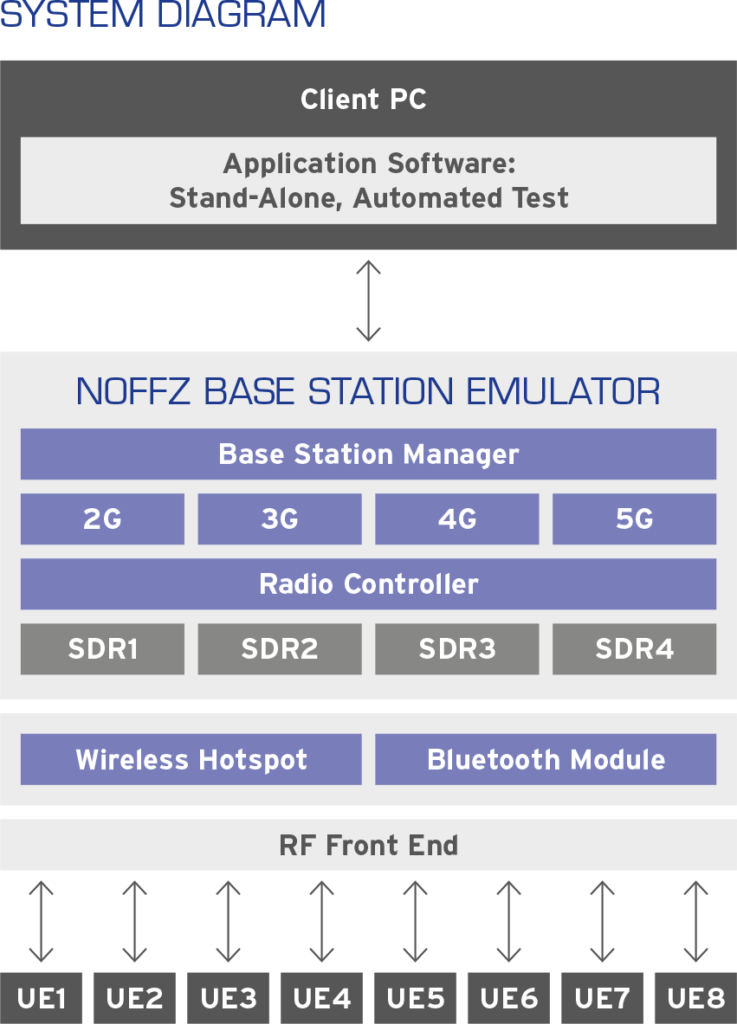

First steps with the Base Station Emulator

Practical implementation of typical test cases

The Base Station Emulator was developed for signaling tests in validation and production. The video series demonstrates typical scenarios: 1. Establishing a cellular connection, 2. Data transmission in 5G network, 3. Calls over VoIP, 4. Hand-over between mobile cells.

FOR YOUR SMART PRODUCTION

Automated UTP 6010 for Telematic Control Unit

Robot-controlled loading and unloading of the NOFFZ HF chamber

In this video, the control of the integrated HF chamber is automated with the help of a collaborating robot arm. It handles the opening and closing of the drawer as well as the insertion and removal of the Telematic Control Unit.