UTP 50XY Adapter Platform

- Home

- UTP 50XY Adapter Platform

UTP 50XY Adapter Platform

Test adapters for board-level and end-of-line testing

Flexible Adapter Platform for all applications in Validation and Production

The NOFFZ UTP 50XY test adapters combine maximum flexibility with high reliability. They feature a modular design, are CE-compliant, and are built to support a wide range of test requirements – from high-density board-level testing to RF-shielded end-of-line testing in mass production.

Whether you are testing a PCB or a finished end product, the UTP 50XY platform adapts precisely to your DUT design and process workflows. This enables efficient integration into existing test systems while ensuring the highest test quality with minimal effort.

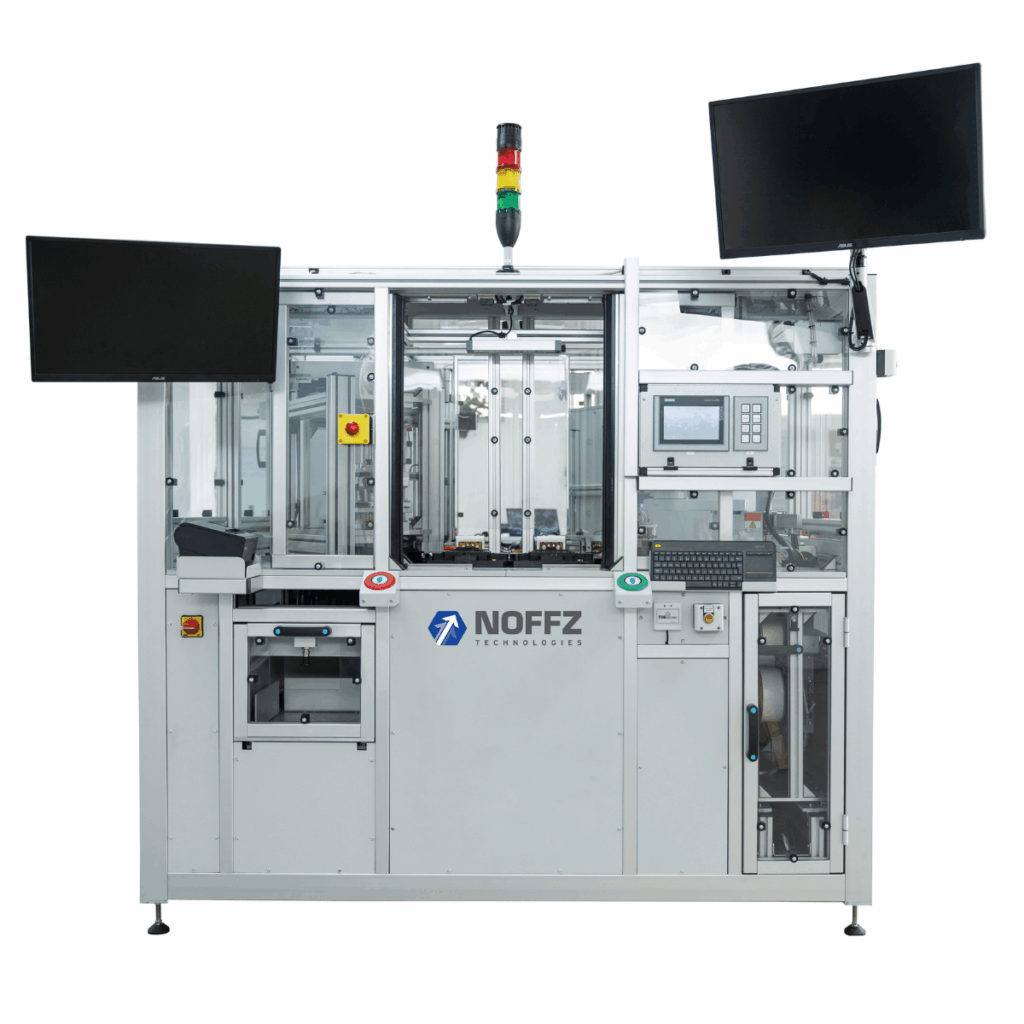

The NOFFZ adapter platform is designed for seamless integration into modern production environments – from semi-automated lines with human operators to fully automated robotic systems. With a wide selection of standard sizes and customized solutions, it meets the precise needs of your application. Compact, modular, and robust in design, it combines high reliability with maximum versatility and automation capability.

The platform is ideal for efficient board-level testing as well as end-of-line inspections. It remains fully flexible: in fully automated operations, during manual ramp-up phases, or in fallback scenarios. This makes it a secure and future-proof solution for dynamic production requirements.

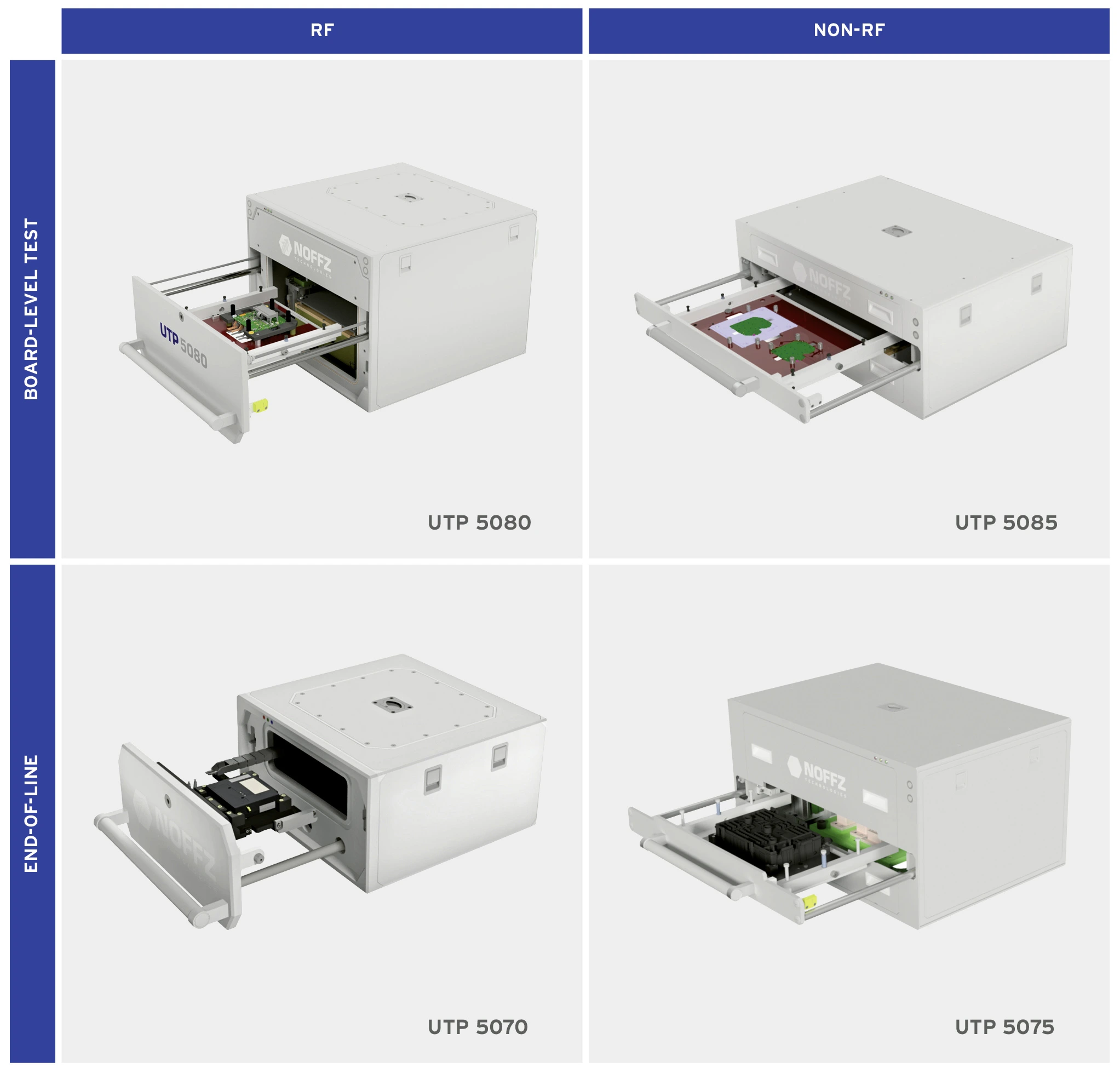

The UTP 50XY supports seamless BLT-to-EOL testing for RF and non-RF applications – flexible, scalable, and optimally integrable.

Testing solutions

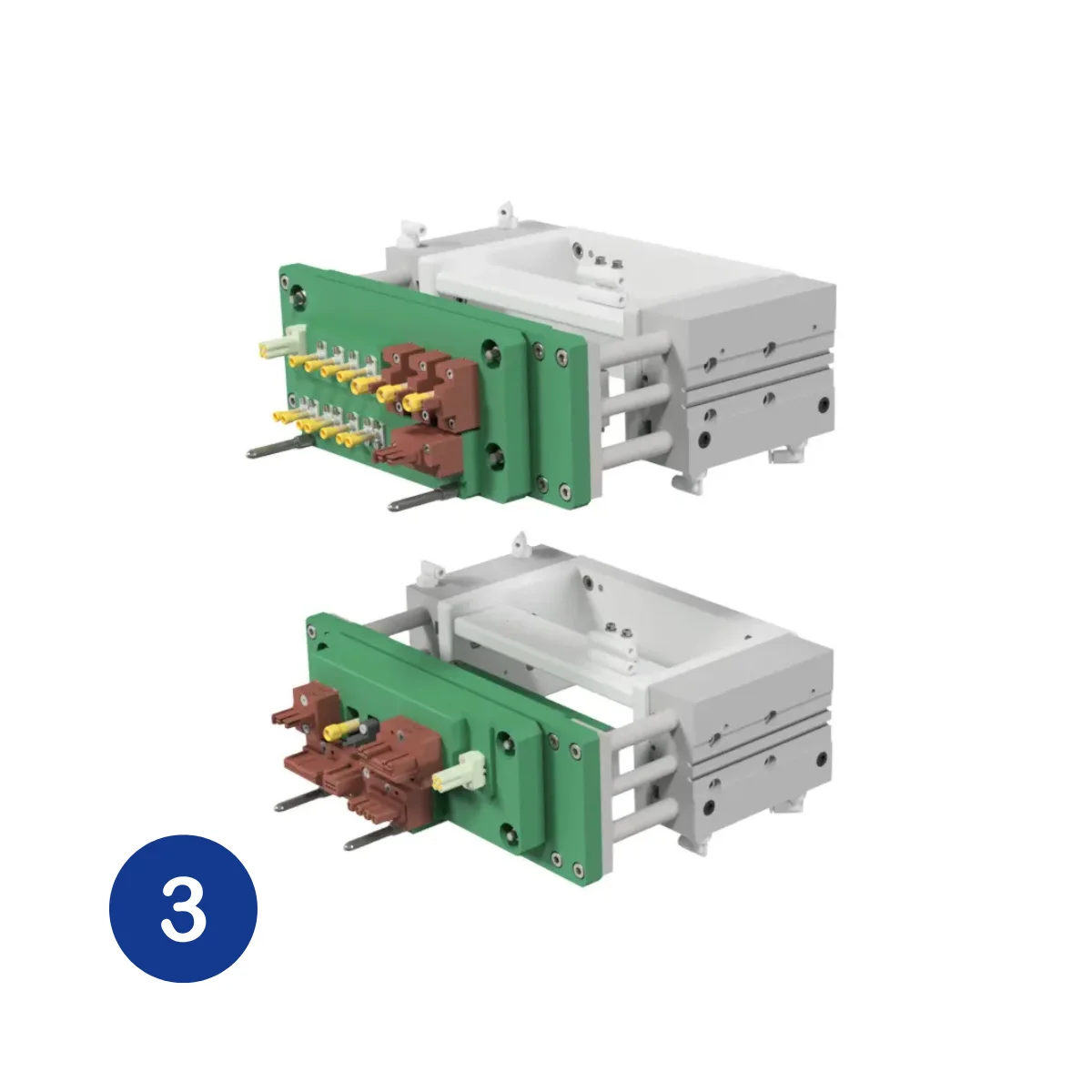

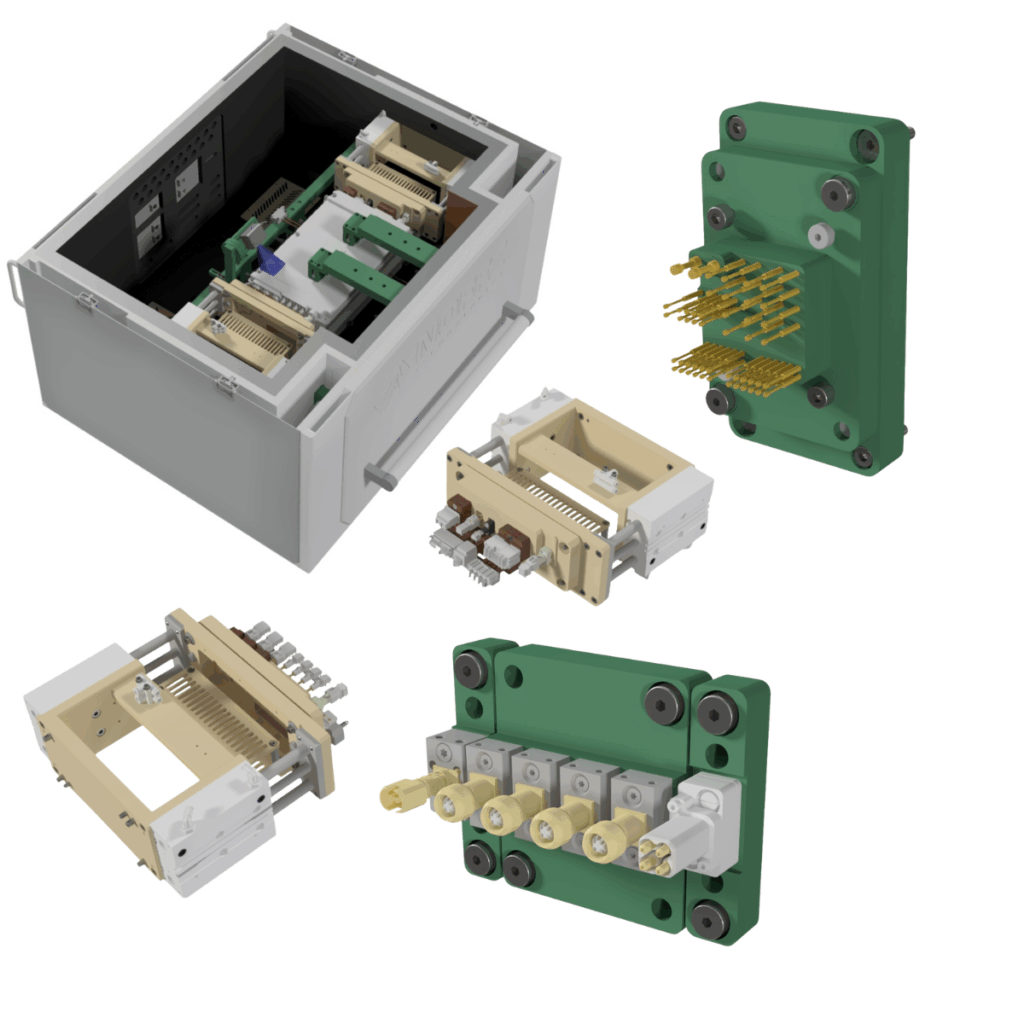

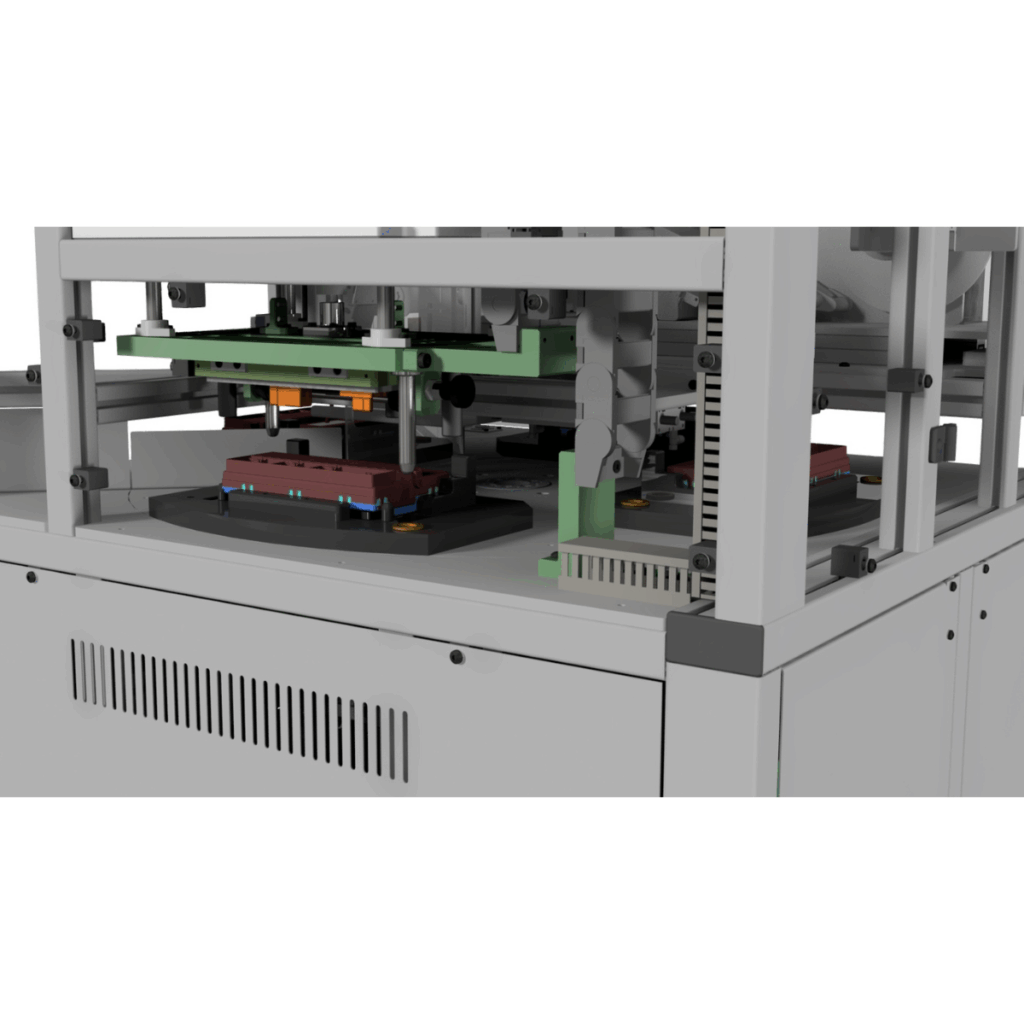

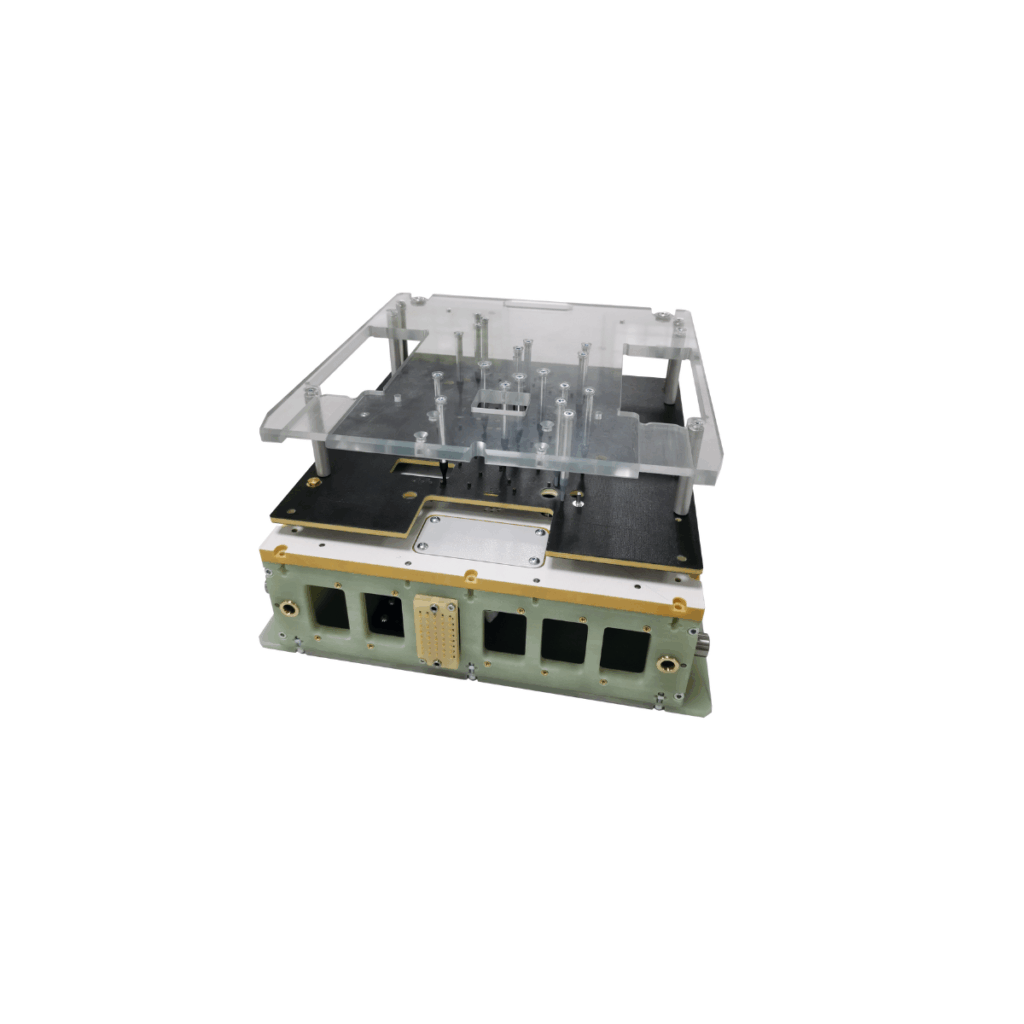

1. End-of-line contact solutions – from simple connectors to the integration of high-speed signal test probes, combined into complex connection networks for testing infotainment devices.

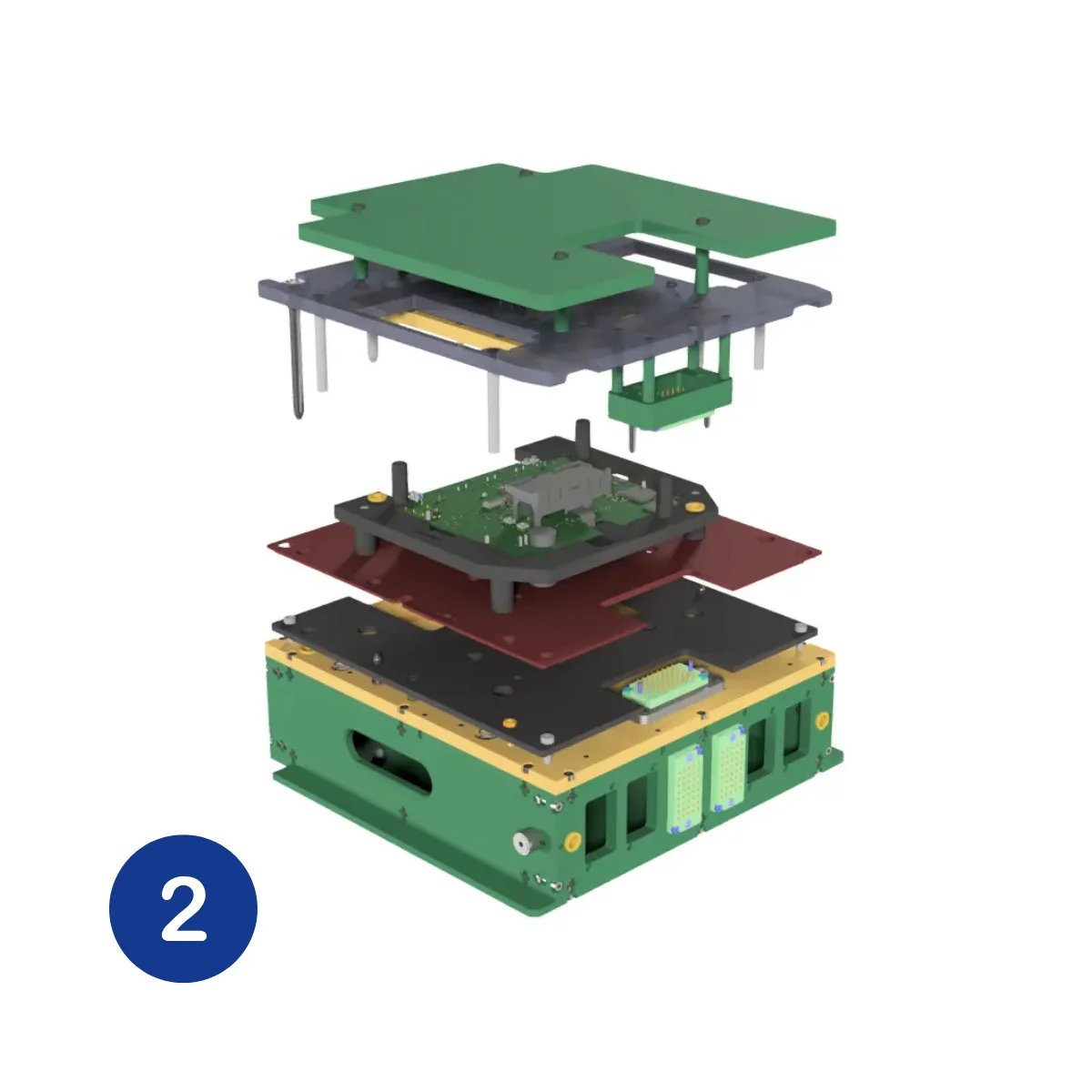

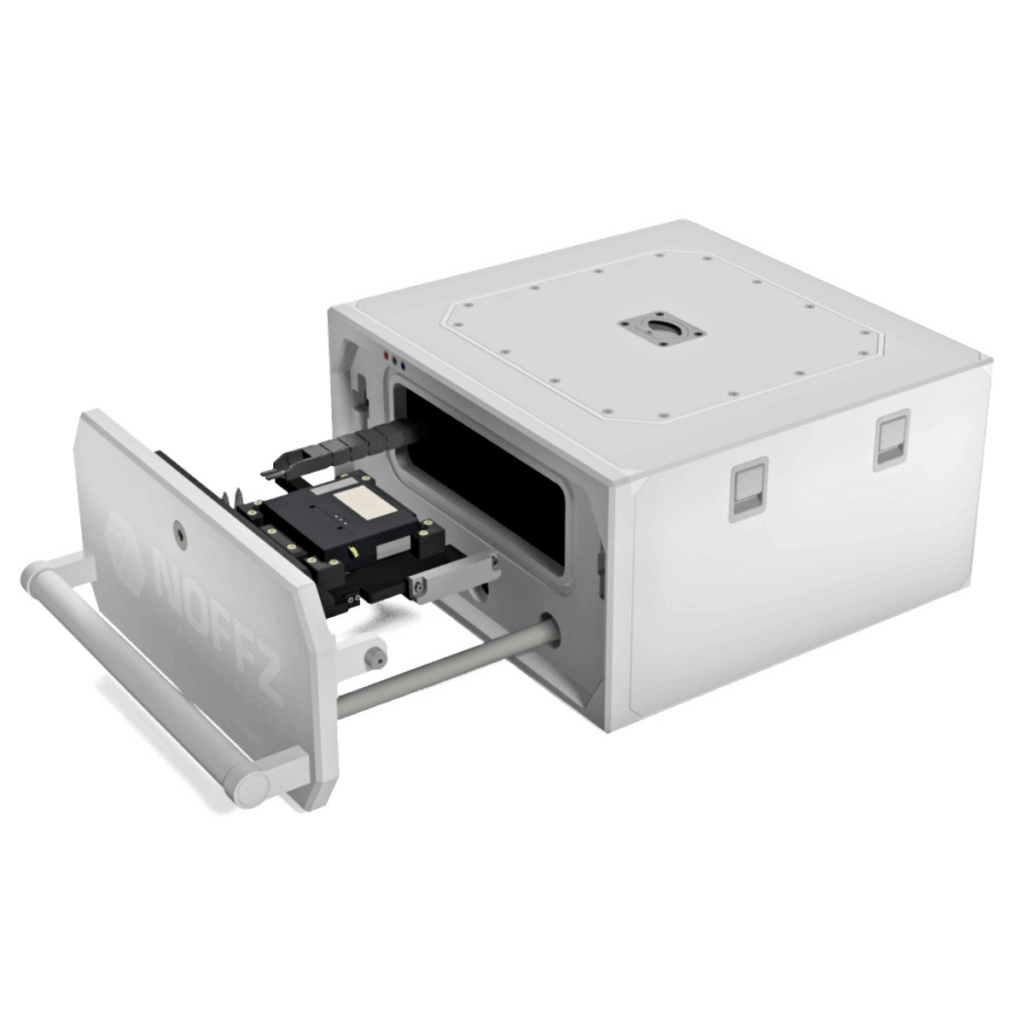

2. Solutions for contacting at the PCB level – compatible with standard and RF devices, interchangeable, suitable for double-sided contacting, including various optional additional components.

3–4. Comprehensive expertise and the flexible design of the adapter platform enable fully automated contacting solutions that can be integrated into various system configurations and combined with additional processes.

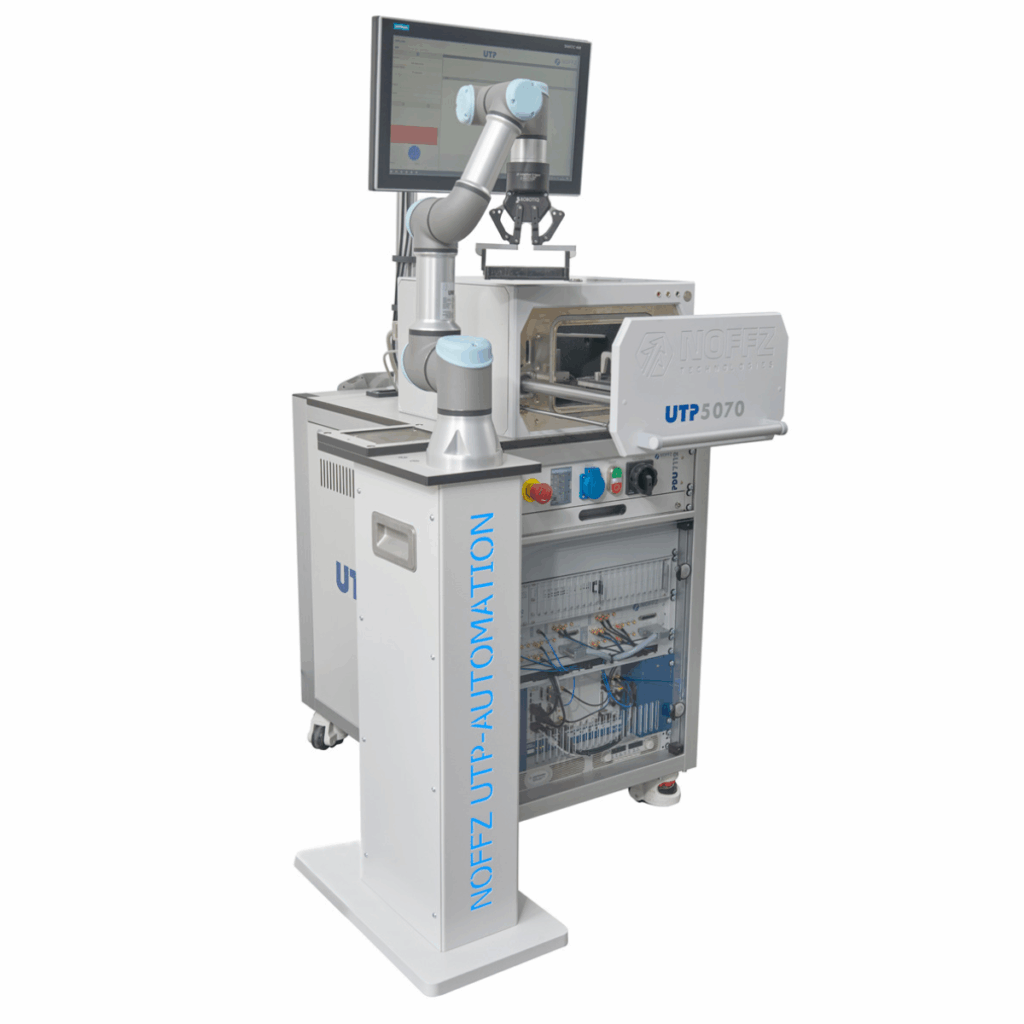

UTP 5070

RF End-Of-Line Testing

- TP CBA Height: Supports boards up to 50 mm high.

- Working Area: Up to 400 x 300 mm – ideal for mid-size PCBs.

- Contact Force: Up to 1800 N for secure, reliable connections.

- Signal Capacity: Up to 1360 interface signals for complex test setups.

- All-Side Contacting: Test connectors accessible from all sides.

- Automation Ready: Stackable and available as semi- or fully automated system.

- Exchangeable contact blocks

- CE Compliant: Meets all applicable safety and quality standards.

- Classical single direction contacting.

- Double or multiple directions contacting.

- Variety of standard probes and custom connectors.

- Fixed or automated contacting units.

- Active cooling during test (liquid or air based cooling).

- Air cooling system test (vibrations and air flow).

Maximum DUT size (W x D):

Small chamber: 150 mm x 200 mm

Medium chamber: 250 mm x 200 mm

Large chamber: 350 mm x 250 mm

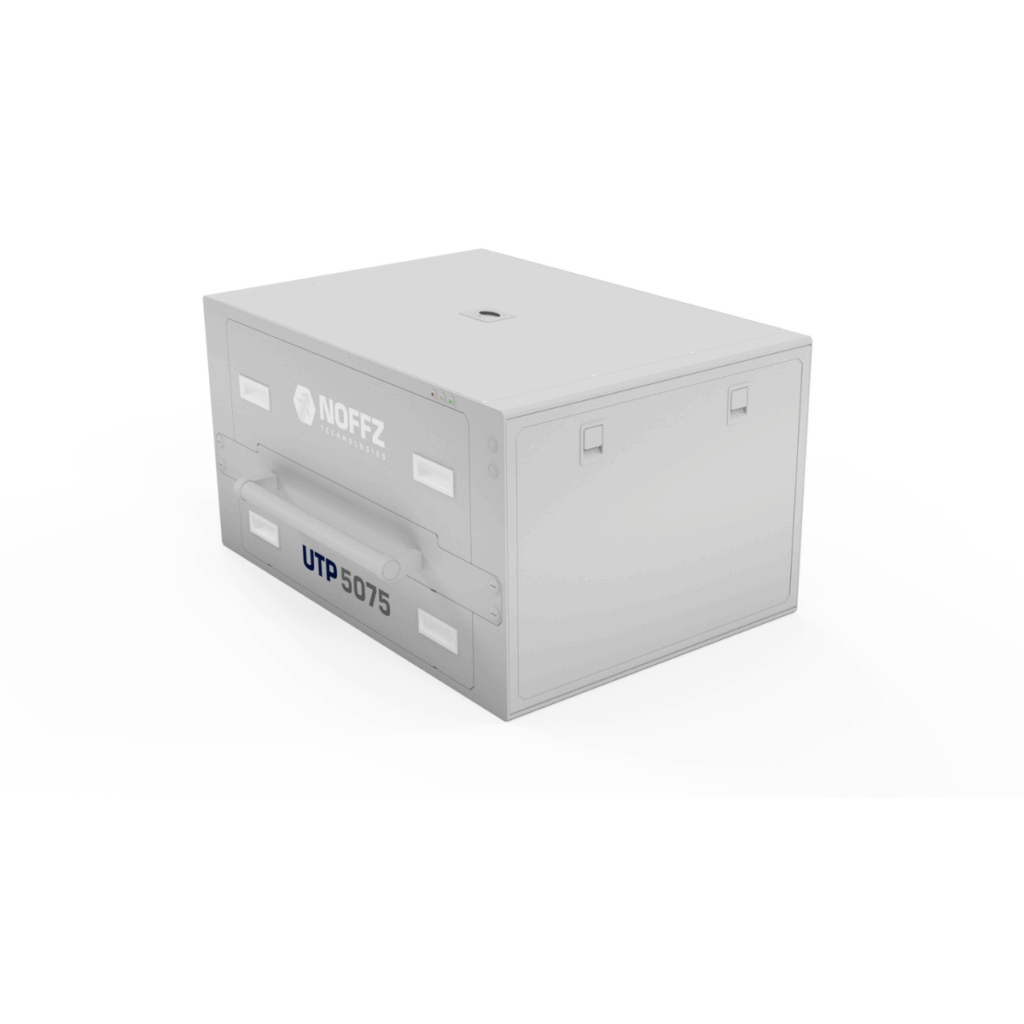

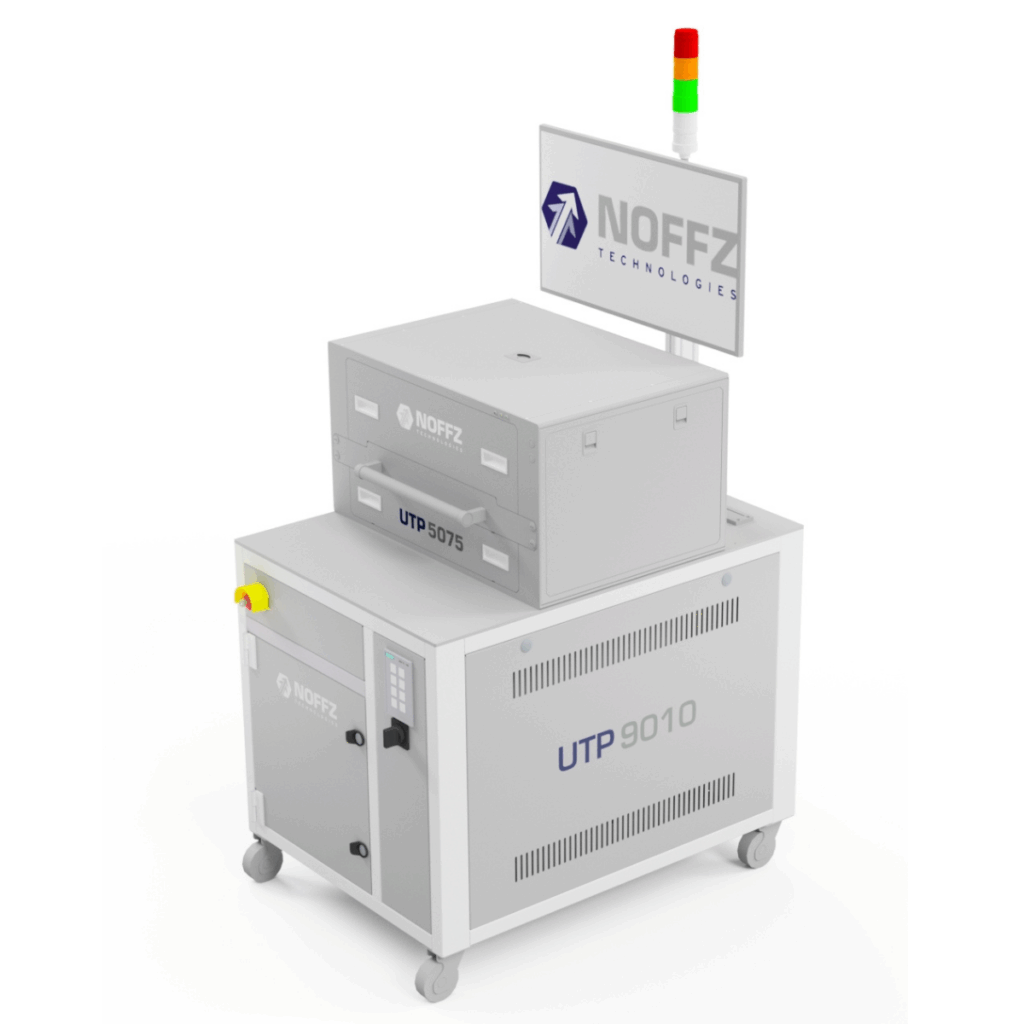

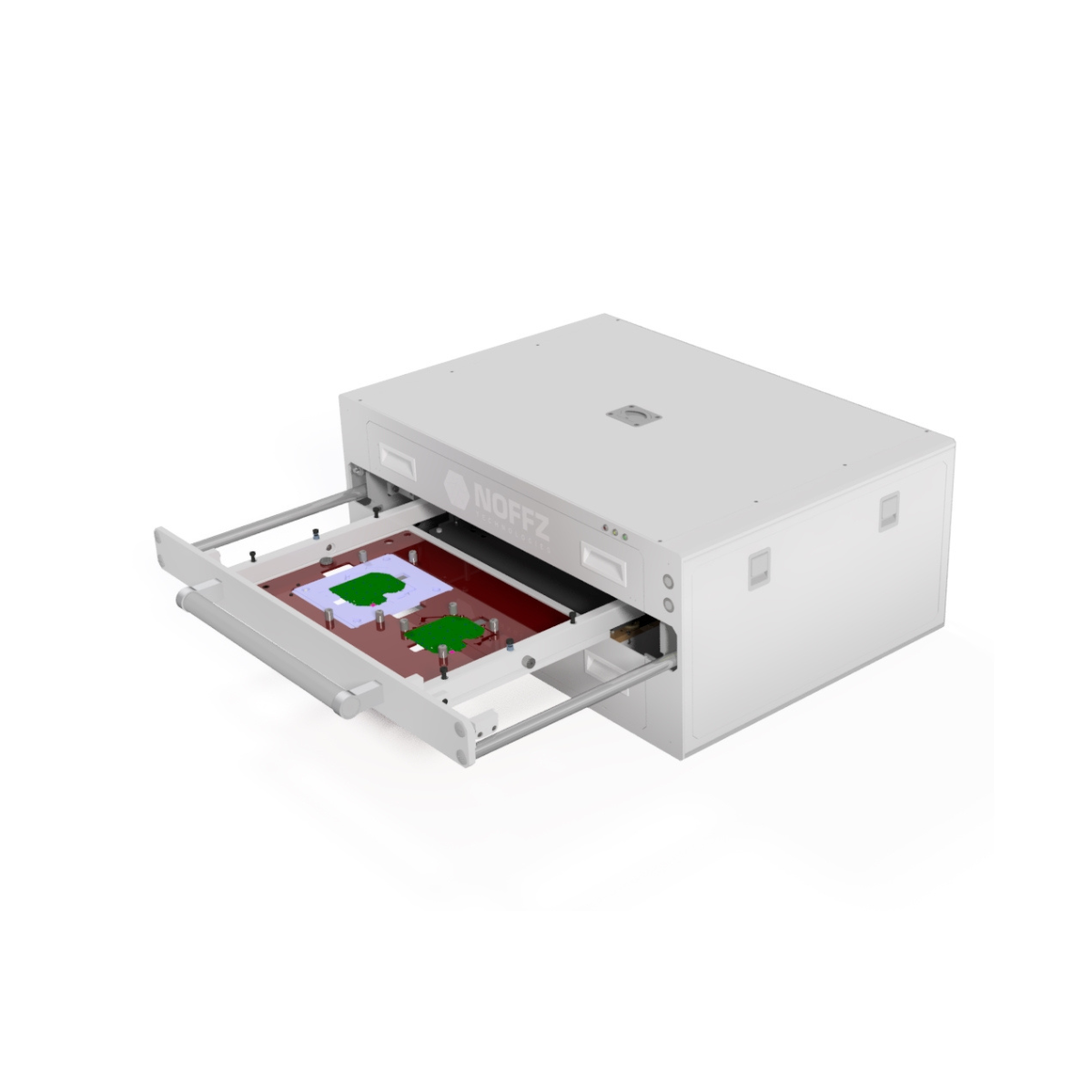

UTP 5075

NON-RF End-Of-Line Testing

- TP CBA Height: Supports boards up to 50 mm high.

- Working Area: Up to 400 x 300 mm – ideal for mid-size PCBs.

- Contact Force: Up to 1800 N for secure, reliable connections.

- Signal Capacity: Up to 1360 interface signals for complex test setups.

- Dual-Side Contacting: Test points accessible from top and bottom.

- Automation Ready: Stackable and available as semi- or fully automated system.

- Cassette System: Supports both fixed and exchangeable cassettes.

- CE Compliant: Meets all applicable safety and quality standards.

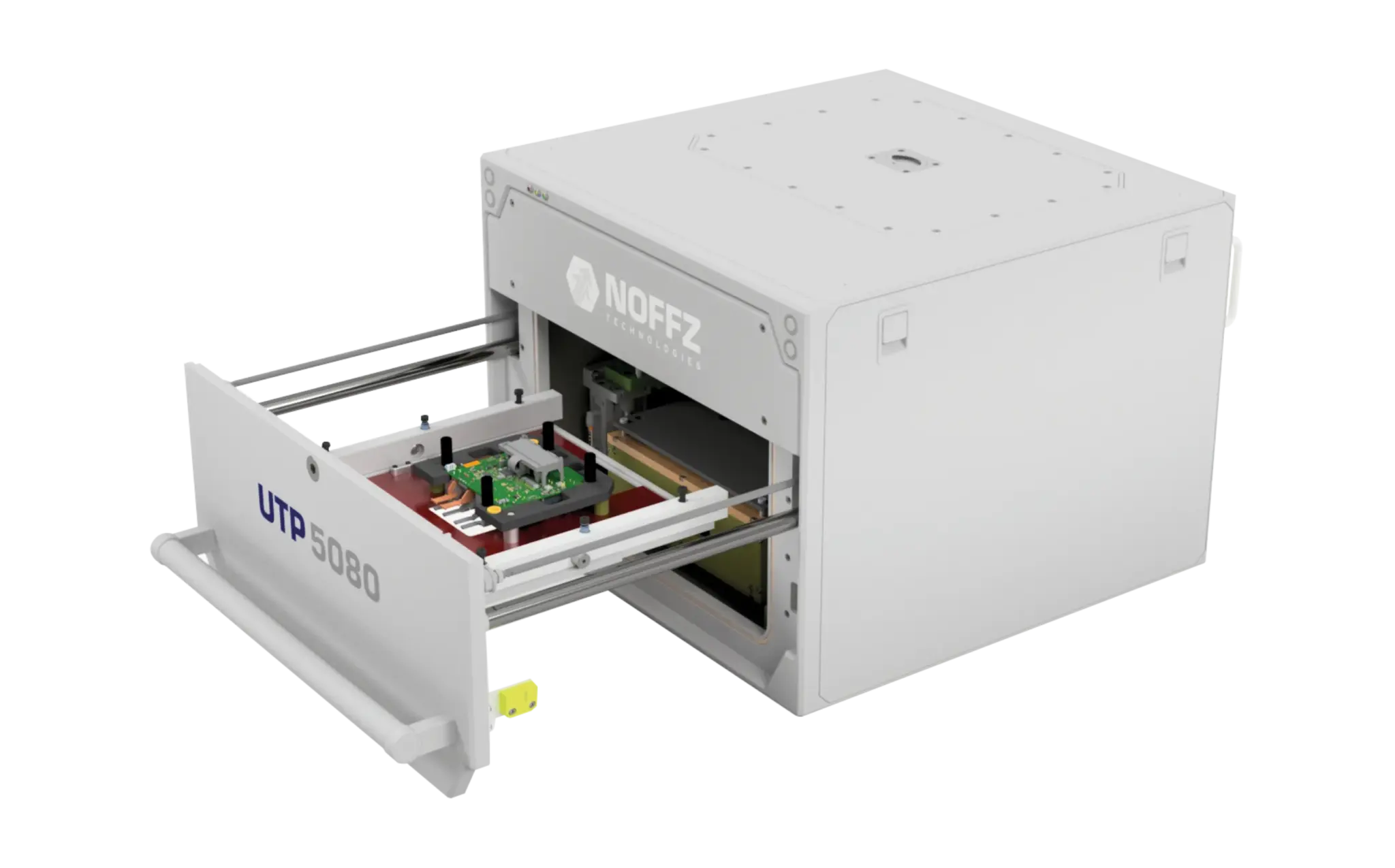

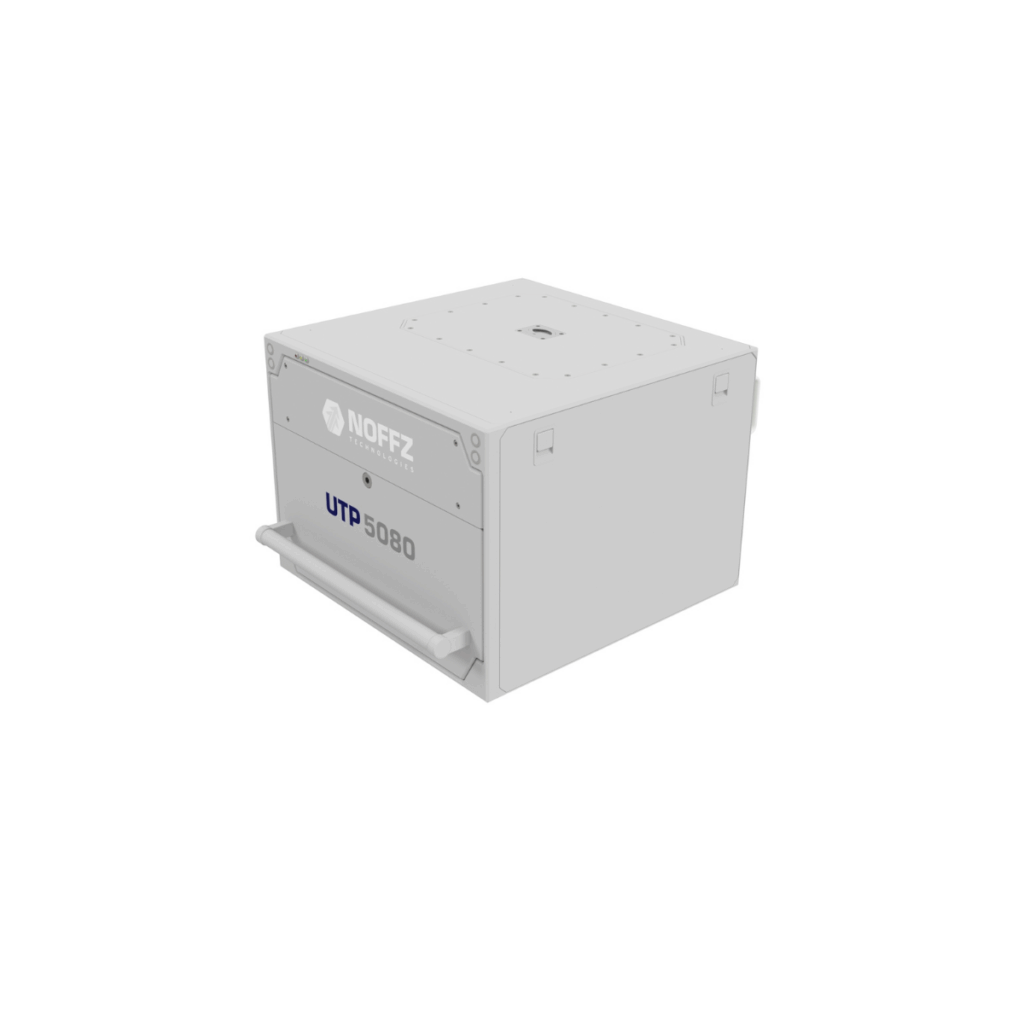

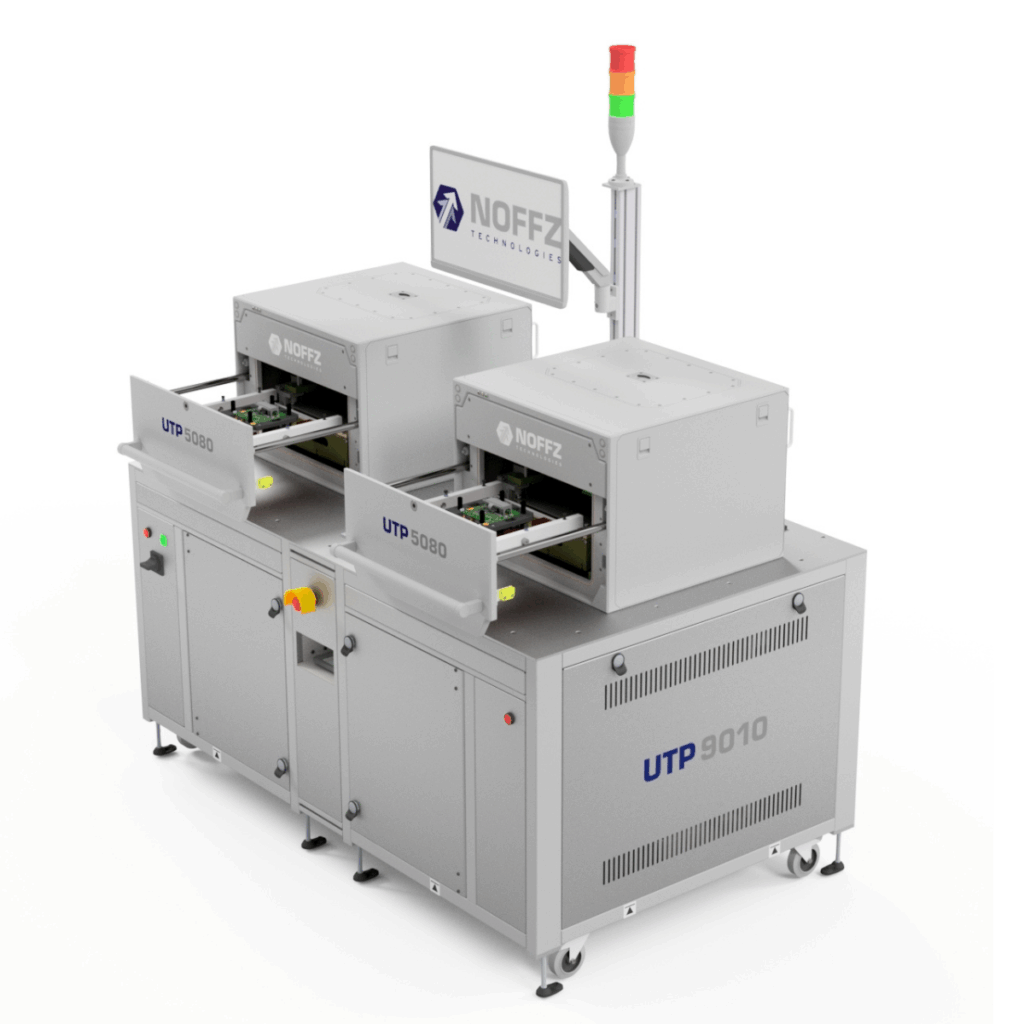

UTP 5080

RF Board-Level Testing

- DUT Height: Supports devices up to 50 mm high.

- Working Area: Up to 250 x 225 mm – ideal for compact to mid-size PCBs.

- Contact Force: Up to 1200 N for secure, reliable connections.

- Signal Capacity: Up to 1020 interface signals for complex test setups.

- Dual-Side Contacting: Test points accessible from bottom and top.

- Automation Ready: Stackable and available as semi- or fully automated system.

- Cassette System: Supports both fixed and exchangeable cassettes.

- CE Compliant: Meets all applicable safety and quality standards.

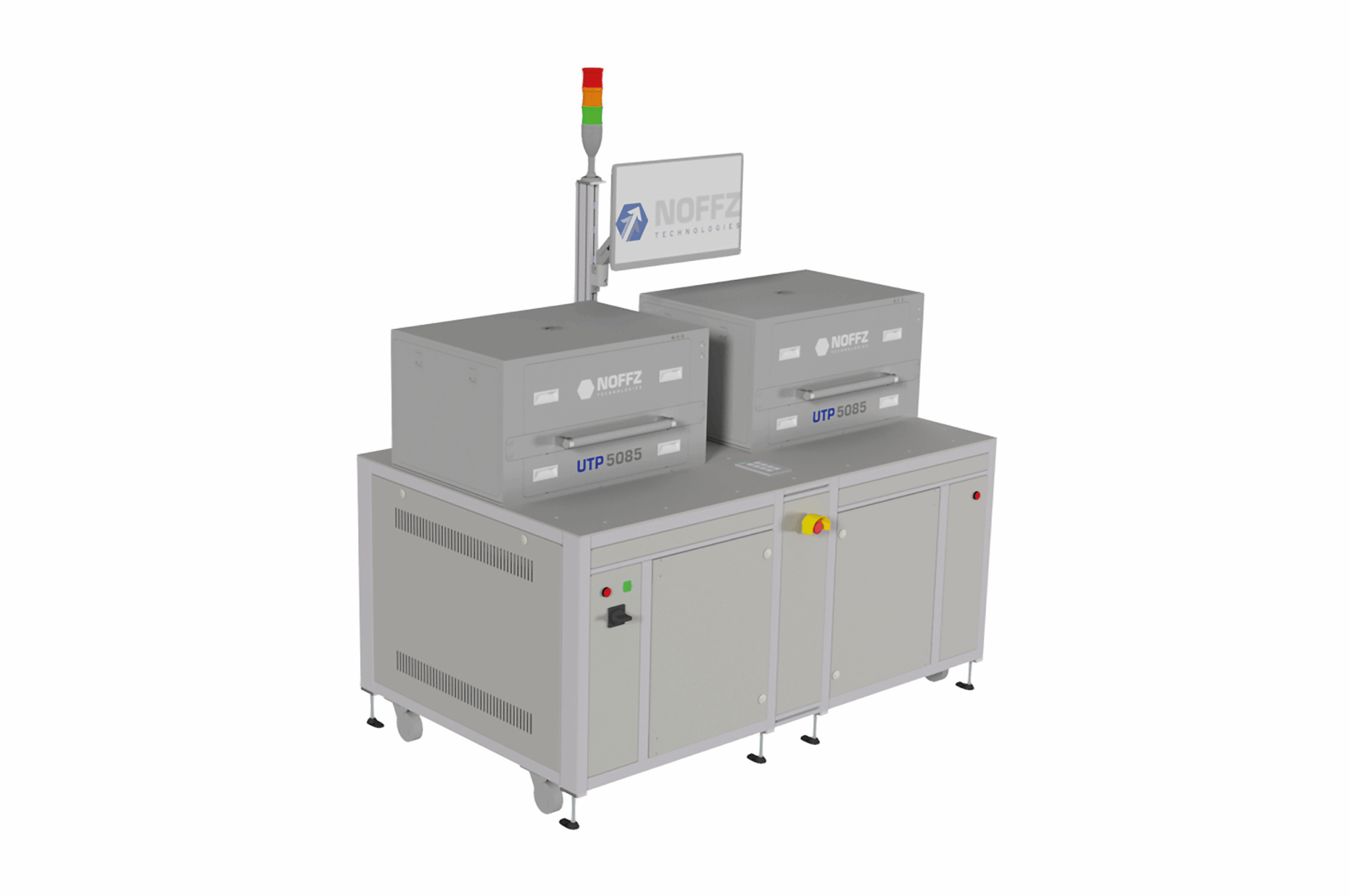

UTP 5085

NON-RF Board-Level Testing

- DUT Height: Supports devices up to 50 mm high.

- Working Area: Up to 400 x 300 mm – ideal for mid-size PCBs.

- Contact Force: Up to 1800 N for secure, reliable connections.

- Signal Capacity: Up to 1360 interface signals for complex test setups.

- Dual-Side Contacting: Test points accessible from top and bottom.

- Automation Ready: Stackable and available as semi- or fully automated system.

- Cassette System: Supports both fixed and exchangeable cassettes.

- CE Compliant: Meets all applicable safety and quality standards.

All advantages at a glance

End-of-Line Tester

for automotive radar sensors

Extremely low-reflection absorber chamber

See all the advantages of our testing system at a glance The UTP 5065 offers the necessary flexibility and adjustability for the validation and production test of modern radar sensors.

Example of Application

Application example for adapter platform 50xy

SINGLE ADAPTER SYSTEM (1-UP)

Ideal for lower capacities, yet supports complex testing requirements. By combining manual or automated adapters with standard UTP-6010 or UTP-9010 racks, it enables reliable testing with minimal space requirements. Suitable for compact production lines, it offers efficiency and ease of use with a single adapter configuration.

DUAL-ADAPTER SYSTEM (2-UP)

Designed for increased capacity or phased testing, where complex test requirements are divided into subsets and executed in separate adapters. When using manual or automated adapters with a standard UTP 9011 rack, this dual configuration supports higher throughput, optimizes space requirements, and boosts productivity.

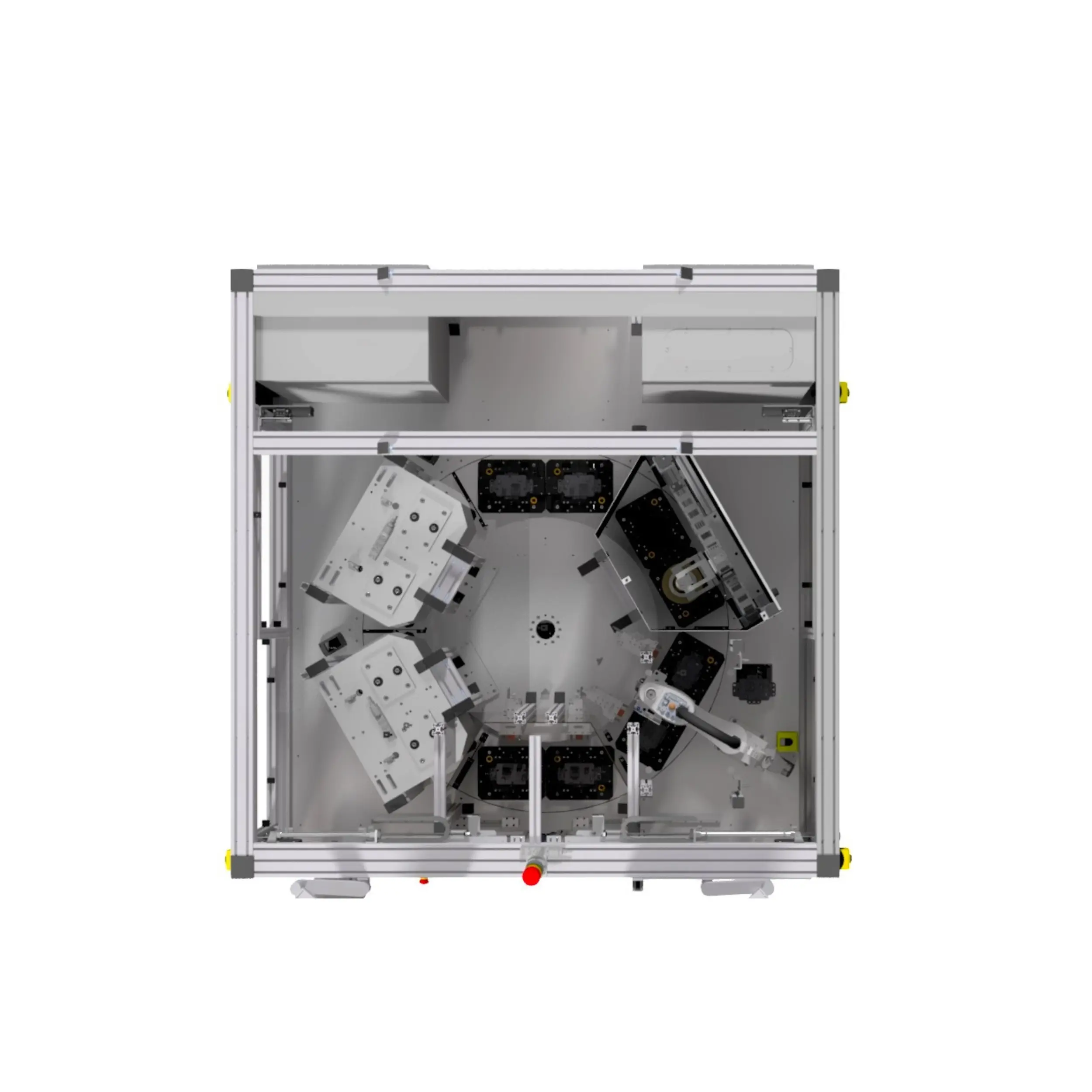

HIGH-PERFORMANCE 10-UP SYSTEM

Designed for high-volume testing with the option for robotic automation. Supports a combination of standard and RF test adapters in typical or 19-inch sizes and saves space through stacked configurations. Offers flexibility for various products and enables future scalability with expanded capacity in automated systems.

Downloads

Our brochures for download

DO YOU HAVE ANY QUESTIONS?

Speak with our experts directly!

Let us know the details of your project. We’re curious about your ideas, products, and requirements and would be glad to advise you specifically about your requests.

Together we’ll make your project a success!

Let’s set up a meeting.